|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

high pressure triplex mud pumps for sale

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Specifications

1) Power: 1300HP

2) API certified.

3) Top grade quality

4) Longer stroke.

5) Strong structure

6) Quick delivery

7) Good service

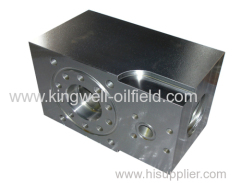

1. Kingwell F Series Mud pump Desciption:

Features of F Series Triplex Mud Pump:

Product Range: F-500, F-800, F-1000, F-1300, F-1600, F-2200

A solid and compact structure, miniature volume, good and reliable performance, which can meet the drilling requirements such as high pump pressure and big displacements in the oil field.

F series mud pump has a longer stroke and can be operated at a lower stroke, thus improved the water supplying performance effectively and extended the lifetime of expendable parts in the fluid end greatly. The suction pulsation dampener has an advanced structure which is reliable to use and can make the pump realize its best suction performance.

The power end uses combined lubricating system of forced lubrication and splash lubrication. Reliable to lubricate and promote the service life of power end.

This series mud pumps are widely used in the oilfields and other industrial mining enterprises for well drilling and well repairing etc.

This series mud pump are strictly manufactured according to API Spec 7k "the Equipment Specification of Well Drilling and Repairing", and are tested accordingly when leave factory.

2. Kingwell Mud pump Technical Data:

| Model | F-500 | F-800 | F-1000 | F-1300 | F-1600 |

| Type | Triplex single acting | Triplex single acting | Triplex single acting | Triplex single acting | Triplex single acting |

| Rated Power | 373kw 500HP | 596kw 800HP | 735kw 1000HP | 969kw 1300HP | 1193kw 1600HP |

| Rated Speed | 165 SPM | 150 SPM | 140 SPM | 120 SPM | 120 SPM |

| Stroke(mm/inch) | 190/7 1/2″ | 228.6/9″ | 254/10″ | 305/12″ | 305/12″ |

| Max.Liner Dia. | 170/6 3/4″ | 170/6 3/4″ | 170/6 3/4″ | 180/7″ | 180/7″ |

| Gear Type | Herringbone | Herringbone | Herringbone | Herringbone | Herringbone |

| Valve Pot | API-5 | API-6 | API-6 | API-7 | API-7 |

| Gear Ratio | 4.286:1 | 4.185:1 | 4.207:1 | 4.206:1 | 4.206:1 |

| Suction Inlet | 203/8″ | 254/10″ | 305/12″ | 305/12″ | 305/12″ |

| Discharge Inlet | 4″Flange 5000 psi | 5″Flange 5000 psi | 5″Flange 5000 psi | 5″Flange 5000 psi | 5″Flange 5000 psi |

| Lubrication | Forced& Splash | Forced& Splash | Forced& Splash | Forced& Splash | Forced& Splash |

| Max. Pressure | 27.2Mpa 3945 psi | 34.5Mpa 5000 psi | 34.5Mpa 5000 psi | 34.5Mpa 5000 psi | 35Mpa 5080 psi |

| Overall Size(in) | 144*106*86 | 156*79*66 | 163*89*70 | 174*121*78 | 181*129*106 |

| Weight(kg) | 9770 | 14500 | 18790 | 24572 | 24791 |

1. Forged Brass Cylinder

2. Anodized Aluminum Crank Case

3. Durable Water Seal & Oil Seal

4. Stable Ceramic Coated Plunger

6. Precise, Hardening Crank Shaft

7. Pressure Adjustable

8. Water Filter Built-in

9. Performed Bearings

10. Quick Connector Mounted

Optional:

Over-pressure Protective Nut

Over-heat Protective Valve

Pressure Gauge

Detergent Injector

Application:

The pressure pump are widely used for high pressure washer , which are used for cleaning air port, bus station, hotel and any other public cleaning and sanitation or disease control,

They are also used in villa or park and garden for cleaning and watering, and also for fog system: for making temperature lower, dust falling , beautifying environment and making air fresh.

They also used on farm or in greenhouse, for making fog system and spraying pesticide, and in livestock, for cleaning and disease control.

The can also be used in textile industrial work for humidification.

We also supply the mud pump spare parts as below:

Why you choose Kingwell as your pump supplier:

1). Technical Support and Production Ability: Although we are one relatively new company, but we have the most professional engineers with tens of years experience in mud pump. And we have hundreds of highly skilled workers working on the pump parts and pump assembling with numerous advanced machines. Our production ability has been siteaudited by supervising inspectorate like France BV (Bureau Veritas), DNV(Det Norske Veritas) and SGS-CSTC(Standards Technical Services Co., Ltd.)

2). Quality Assurance: Ten professional inspectors performstrict quality inspection from the initial forgings, castings, other rawmaterials, each finished machined parts until the final assembling of the pump. Each part assembled on the pump will be well tested and highly qualified. Andfor each pump finished, it will be running tested in our test center for atleast 4 hours. Quality certificate, Inspection report and testing report will beattached when pump is delivered. 12 Months quality guarantee will be offered for each pump.

3). Competitive Price: We are one of the top pump manufacturers in China. We have the greatest advantages in price. We can not offer you the lowest price in China, but most competitive price but with very good quality.

4). Quick Delivery: Usually we will keep some pump model in stock so that we can make fast delivery for clients with urgent need. For pump we do not have in stock, we can also deliver with 40 days.

5). We can offer unitized pump package according to your different needs.