|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

Bi-metal Cylinder Liner API Mud Pump Cylinder Liners

| Price: | 10.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

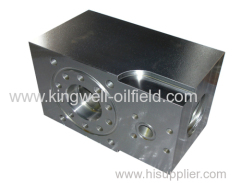

Product Detail

API 7K standard,

OEM interchangeable parts with emsco, gardener denver, national, ideco, bomco

Fast delivery time

High quality with favorable price

Mud Pump Liner Description:

Material: The material of cylinder liner is ZG45 steel, lined with high chromium cast iron. The HRC of cylinder inside liner is 60-65;

Production Process: The bi-metal cylinder Liner of our company combined with the advantages of abrasion hot-forging out liner and anticorrosion high chrome inner liner. The out liner is made of high quality carbon steel by hot pressing forming. Its tensile strength is over 900000psi. The inner liner is made of high-chromium alloy by centrifugal casting.

Application: Bi-metal cylinder liner is one of the most widely and largest used mud pump fluid end fittings.

The mud pump bimetal liner specification as following:

Name | bimetal Liner for Mud Pump |

Process | Forgings |

Inner Sleeve Material | highchrome |

Colour | As you determine, our acquiescent green |

HRC requirement | 59-67 |

Packaging | steel frame, wooden board, and metal strap |

Insurance | According to payment terms |

Delivery | approx. 25 days after order, depending upon order quantity |

Payment | By T/T, 30% down payment and the balance pay off before delivery |

MOQ | 1 pic |

Service cycle | Hi-chrome Bimetal liner more than 800 hours, Zirconia ceramic liner more than 4,000 hours |

Quality Guarantee | 6 months from delivery date |

Quotation Validity | Within 30 days |

We can also supply other parts for mud pump:

1 Fluid End Parts

Nut

Double-Head Bolt

Discharge Manifold

O ring

Fluid End Assembley

Liner End Cover

Spray pipe Assembly

Bolt

Thread Plug

Blind Flange

Suction Manifold

Suction Capsule

Suction Pulsation Dampener(End cover)

2 Crankshaft Assembly

Big ring Gear

Retainer

Stop ring

Main bearing

Main bearing bush

Spacer ring

Hollow crankshaft

Outer stop ring

Excebtric bearing

Connection rod

Position ring

Inner stop ring

3 Valve assembly

4 piston assembly

5 Fluid end module

6 valve cover

7 Liner cage

8 Liner nut

9 valve seat puller

10 Guide and crooshead

11 Cylinder cover flange

12 Extension rod and piston rod

Features of Kingwell mud pump liner:

1). The average working time of bimetal liner is more than 800 hours, of ceramic liner is 4000-1000 hours.

2). The product has various advantages, such as wear-resistance, erosion-resistance, high pressure-resistance, high hardness, and so on.

3). They are widely used in tough environments such as deep oil reservoirs, hard stratum, and offshore oil and natural gas exploitation. The liners with highwear and erosion resistance, and high hardness.

4). They can improve drilling efficiency and reduce the cost of maintenance andlabor.

.jpg)