|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

KINGWELL High Quality Downhole Motor

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

API Downhole Drilling Motor

Packaging Details:EXPORT STANDARD SEAWORTHY PACKING

with competitive price and good quality

factory direct

KINGWELL Downhole Motor

Features & Benefits:

KINGWELL Downhole Motor is a powerful and reliable positive displacement motor. Using the latest available

technology and materials, it can be configured to answer specific downhole conditions or well designs. The

motorgenerates an optimum balance of rotational speed and high torque to drive a variety of drill bits at speeds

that maximize tool life and performance.

KINGWELL MOTORS are used in applications such as straight hole drilling, directional (steerable) drilling,

horizontal drilling, hole opening, and re-entry(work over).

Technology advantages: adjustable bend housing; anti-break device on drive shaft; anti-drop device on rotor;

non-magnetic material etc.

Outstanding technology & project: Many CAE technology are applied to the project, such as contact analysis,

hydraudynamics analysis, static finite element analysis etc.

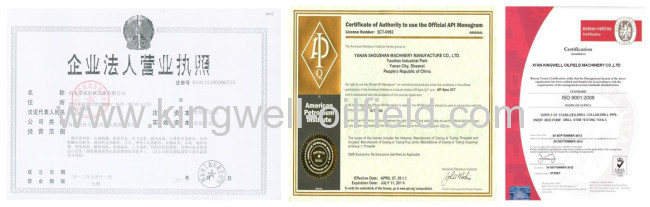

Quality and service system: ISO global quality system is the main quality management standard; API symbol

utility supplies the complete control. Additionally, strong technological service team supplies the technical guide

and help timely.

Technical Data:

| Flow Rate | Pressure Drop | Rating Torque | Max.Torque | Bit Weight | Power | OD | Length | Connections | ||

Box up | box down | ||||||||||

5LZ43×7.0 | 0.5~1.5 | 108 | 173 | 6 | 3.68 | 43(11/16) | 3.3 | M27*2 | |||

5LZ60×7.0 | 1.26~3.13 | 2.5 | 160 | 280 | 5 | 2.35~6.03 | 60(23/8) | 3.3 | 1.9TBG | ||

5LZ73×7.0 | 1.26~5.05 | 3.5 | 275 | 480 | 12 | 3.5~13.82 | 73(27/8) | 3.45 | 23/8 TBG | 23/8 REG | |

5LZ89×7.0 | 2~7 | 4.1 | 560 | 980 | 18 | 5.6~19.35 | 89(31/2) | 4.67 | 23/8 REG | ||

5LZ95×7.0 | 4.73~11.04 | 3.2 | 950 | 1240 | 21 | 10.4~23.79 | 95(33/4) | 3.7 | 27/8 REG | ||

C5LZ95×7.0 | 5~13.33 | 6.5 | 1490 | 2384 | 55 | 21.8~59.3 | 95(33/4) | 6.88 | 27/8 REG | ||

5LZ100×7.0 | 4.73~11 | 3.2 | 710 | 1240 | 21 | 10.4~23.79 | 100(37/8) | 4.35 | 27/8 REG | ||

5LZ120×7.0 | 5.78~15.8 | 2.5 | 1300 | 2275 | 55 | 9.5~27.23 | 120(43/4) | 4.88 | 31/2 REG | ||

C5LZ120×7.0 | 6.667~20 | 5.2 | 2500 | 4000 | 55 | 70.5 | 120(43/4) | 6.88 | 31/2 REG | ||

D5LZ120×7.0 | 5.78~15.8 | 1.6 | 900 | 1440 | 55 | 6.6~18.85 | 120(43/4) | 3.29 | 31/2 REG | ||

3LZ165×7.0 | 17~27 | 4.1 | 2500 | 3750 | 80 | 78.54 | 165(61/2) | 6.5 | 41/2 REG | ||

5LZ165×7.0 | 16~28(47) | 3.2 | 3200 | 5600 | 80 | 33.5~59.65 | 165(61/2) | 6.25 | 41/2 REG | ||

D7LZ165×7.0 | 18~28 | 2.5 | 2300 | 3680 | 80 | 30.4~47.2 | 165(61/2) | 4.7 | 41/2 REG | ||

9LZ165×7.0 | 19~31.6 | 2.5 | 3200 | 5600 | 100 | 45.24 | 165(61/2) | 5.7 | 41/2 REG | ||

Pictures

Company Introduction

Xi'an Kingwell Oilfield Machinery Co.,Ltd is an established, financially stable manufacturing company and manufactured products are technically qualified which match the highest quality & reliability standards. We fulfill all the requirements to become a reliable supplier of any National and International majors in this field.

Here we got some prise as follows.

Design & Development

Kingwell has an ongoing relationship with Xi'an Petroleum University and built up long term cooperation with China Aerospace Group for more than 10 years. Design Department is familiar with CAD and Pro-E facilities and has on rolls qualified & experienced engineers. Now, they are engaged in development of new products as required in the market place. Kingwell' products are validated in-house in a Test Well, a Sub-surface Type Test Facility with simulated well conditions up to 15000 psi Differential pressure , 400°F and Max 450°F.

Below are our cooperative partners.

Manufacturing Facility

Equipped with latest machining facilities like CNC 3-axis Turning centers, CNC 4-axis milling centre, high temperature heat treatment furnaces, Centre lathe machines, Deep Hole Drilling, Boring & Honing machines, our company could meet long term production target and be governed efficiently by well-qualified and experienced Board of Directors and Engineers.

The following is the manufacturing workshop.

Inspection and Test Facilities

We own the world-class facilities with professional laboratory technicians. The main facilities are Surface Testing (Hydraulic Testing Unit), high temperature heat treatment furnaces, API Gages (Master & Working), Profile Projector, tensile testing machine, pressure sensor and data acquisition system, Universal Testing Machine, Hardness Tester, Nitrogen Pump, Function Test Pump, Ultrasonic Thickness Tester etc. All the goods must be tested by several processes and must be qualified when packed.

The followings are some pictures of Test Facility

We believe in Customer delight, achieved by the supply of Quality Products & Services and Continual Improvement in our Manufacturing Processes for timely delivery at competitive prices. We work in a professional, competitive, and cost-effective manner consistent with the Customer requirement

We are looking forward towards a long lasting association with your esteemed organization for our mutual benefit. Any reasonable documents with the shipments depend on your requirements. Please contact us for any enquiry within our manufacturing scope and we will be happy to serve you by supplying quality products.

.jpg)