|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

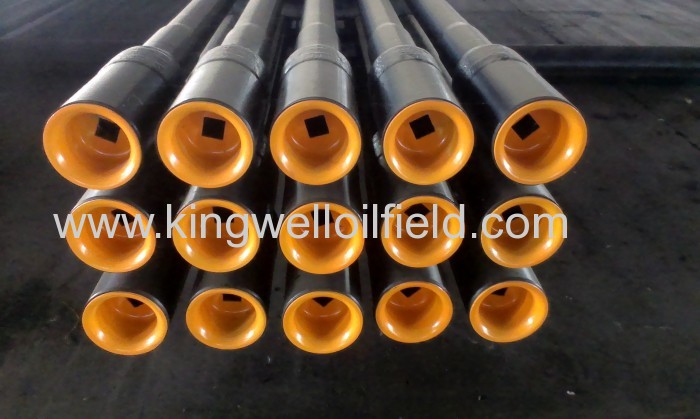

NS-1Drilling Pipe for Oilfield Equipment Downhole Tools

| Price: | 10.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

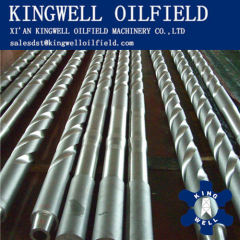

1.Standard: NS-1

2.Material: AISI 4145 H Modified Alloy Steel and Non-mag Material

3.With high quality and steady supply

4.Processing Type: Forging

NS-1Drilling Pipe for Oilfield Equipment Downhole Tools

1.Standard: NS-1

2.Material: X95 G105 S135

3.With high quality and steady supply

4.Main Custums: USA, Canada, Middle East

Kingwell tube and tool joint inspections are carried out in accordance with standards like API, DS-1 and NS-2. Inspections of drill pipes, casings, tubings or tools are usually performed based on the following international standards:

· API, API 5CT, API 5L

· DS1 Cat 1 to 5

· NS1/NS2

NS-1Drilling Pipe for Oilfield Equipment Downhole Tools Detail:

Drill pipe inspection services:

Visual Tube Body Inspection | A thorough visual inspection of pipe external surface for possible noticeable damages, such as dents, mashes and corrosion/ pits, shall be performed from upset to upset. Visual inspection includes internal end area of each tube for service induced defects. The tubes are checked for straightness. |

Visual Thread Inspection | Thread Protectors are removed and both pin and box ends are thoroughly cleaned and visually evaluated for any obvious defects or mechanical damages, such as dents, corrosion, galled threads, etc. |

OD Gauge (Full Length) | Full length mechanical measurement of outside diameter is performed for identification of external wear, dents, mashes, slip area and stress induced diameter variations. |

Magnetic Particle Inspection (MPI) | Pipe is magnetized with a DC magnetizing coil with variable current to provide active longitudinal magnetization for detection of transverse flaws. |

Electromagnetic Inspection (EMI) | Buggy Inspection Unit is used for transverse defect inspection. |

Ultrasonic Inspection (UT) | Ultrasonic examination of upset areas for the detection of transverse and three dimensional flaws on the inside and outside surface of the tube is performed. The critical area is also covered. |

Hardness Testing | Portable Hardness Testers are utilized to perform hardness reading on the pipe. |

Wall Thickness Measurements | Ultrasonic Measurement: Ultrasonic wall thickness tests are utilized to determine the minimum and maximum wall thickness at any one area on a tube. A test consists of taking as many circumferential measurements as required to determine the minimum and maximum wall thickness in one area. |

Tool Joints & Upsets Inspection | Transverse external magnetic particle inspection (excluding threads) is performed to detect external fatigue cracks and pits. |

Company Profile:

Xi'an Kingwell Oilfield Machinery Co.,Ltd is a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provide complete solutions.

With over 10 years developing, we were developed from the beginning drilling service to manufacture factory who produce OCTG, DST tools and Solid Control products.

KINGWELL have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation, our aim is to build solid relationship with any part of honest. kingwell can provide highly efficient services to its clients resulting in accurate and timely deliveries at the best prices.

It is a professional supplier for oilfield products according to the API standard. We exporting ALL KINDS OF OILFIELD MACHINERY AND TOOLS with super Quality and Competitive Price in CHINA.

Qulification:

Packaging:

Export Packaging

About delivery:

If goods are in stock, warehouse machine need 10 days delivery for paint and package, tell us: what colors u need. If every material is ready, 15 days finish the goods.

If material is not ready, 30 days to delivery. Because we still have other order to do at the same time.

.jpg)