|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

API 7-1 drilling tool 4145H heavy weight drill pipe

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

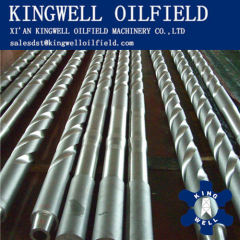

1. API 7-1 Heavy weight drill pipe, HWDP

2. Material: AISI 4145H

3. OD: 3 1/2 --6 5/8"

4.Box Bore Back x Pin Ring Groove

Introduction:

Kingwell is a professional manufacturer of medium and large forgings based in mainland China. We mainly focus on the manufacturing of big size special steel forging which are widely used in great equipment manufacturing industry of oil, electricity, chemical, shipping, metallurgy, machinery and military.

Application of product:

Drill pipe is a portion of the overall drill string. The drill string consists of both drill pipe and the drill stem which is the tubular portion closest to the bit or downhole assembly. Drill pipe and drill stems can be differentiated in that the drill pipe is quite flexible and produced in longer segments whereas the drill stem is much more rigid and manufactured in shorter task specific segments.

Superiority of our product:

Kingwell's integral heavy weight drill pipe are made from AISI 4145H alloy bars that are quenched and tempered full length. A hardness range of 285 to 341 BHM and a minimum impact value of 54 Joules as per ASTM A 370 are maintained one inch bellow the surface at room temperature. To improve resistance to galling, all connections are phosphate-coated with an API thread compond. Each bar used to manufacture kellys has been examined with magnetic partice inspections and ultrsonic inspections.

Production Specification:

1. Product: heavy weight drill pipe

2. Raw material: AISI 4145H

3. Diameter: 2 7/8"-6 5/8"

5. Length: 9300mm/13500mm

7. Delivery time: 30 days after receive the deposit.

8. Process: EAF + LF + VD +(ESR) + Forged + Heat Treatment (optional)

9. Delivery condition: Hot forged, Heat-treatment (Normalized / Annealed / Quenched / tempered), Rough machining.

10.SURFACE FINISHES: Black, Peeled, Turned & Polished

12.Payment: 30% advance by T\T; Balance pay before the shipment against shipping documents or irrevocable LC at sight

13.Technical Data: Chemical Composition, Physical Properties and Mechanical Testing according to the customer's requirement

The following reports provide to the customers to assure our quanlity:

a) Chemical Composition Report

b) Mechanical Properties Report

c) Dimension Test Report

d) Hardness Test Report

e) Heat Treatment Chart Report

f ) UT, MT Test Report

g) Or Others according to clients' demand

Heavy Weight Drill Pipe Specification

| Length | Tube | Tool Joint | |||||||

ID | Wall Thickness | End | Connection | Tool | Tool Joint ID | Per foot | Per Joint (31ft)kg | Make-torque(ft-lb) | ||

2 7/8 | 31 | 1 1/2 | 0.688 | 2 15/16 | NC26(2 3/8 IF) | 3 3/8 | 1 1/2 | 18.31 | 261 | 3,800 |

3 1/2 | 31 | 2 1/16 | 0.719 | 3 7/8 | NC38(3 1/2 IF) | 4 3/4 | 2 1/16 | 27.14 | 390 | 11,500 |

3 1/2 | 31 | 2 1/4 | 0.625 | 3 7/8 | NC38(3 1/2 IF) | 4 3/4 4 7/8 | 2 1/4 | 24.88 | 360 | 11,500 |

4 | 31 | 2 9/16 | 0.719 | 4 3/16 | NC40(4 FH) | 5 1/4 4 7/8 | 2 9/16 | 31.51 | 455 | 14,600 |

4 1/2 | 31 | 2 3/4 | 0.875 | 4 11/16 | NC46(4 IF) | 6 1/4 | 2 3/4 | 43.31 | 621 | 22,500 |

5 | 31 | 3 | 1 | 5 1/8 | NC50(4 1/2 IF) | 6 5/8 | 3 | 52.34 | 750 | 30,000 |

5 1/2 | 31 | 3 1/4 | 1.125 | 5 11/16 | 5 1/2 FH | 7 1/4 | 3 1/4 | 63.87 | 915 | 41,200 |

6 5/8 | 31 | 4 1/2 | 1.063 | 6 5/16 | 6 5/8 FH | 8 | 4 1/2 | 74.62 | 1070 | 50,500 |

Quality control or assurance:

In order to keeping competition and developing, the basic is to improve any possible aspects such as company quality, we place an emphasis on elements includes controls, job management, defined and well managed processes, performance and integrity criteria and identification of records, on competence includes knowledge, skills, experience and qualifications, on soft elements includes personnel integrity, confidence, organizational culture, motivation, team spirit and quality relationship.

.jpg)