|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

Ram Blowout Preventer/BOP API oilfield

| Price: | 1000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Working Pressures:2000PSI-20000PSI (14~140Mpa)

Bore Sizes:7-1/16"-26-3/4"

Performance level: PSL1, PSL2, PSL3

Standard: API 16A

Material: AA to FF

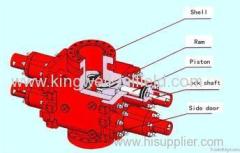

Ram type blowout preventer

Ram BOP is an important part of well-control equipments. It is mainly used to control wellhead pressure during drilling, workover operations and formation testing etc to prevent well blowout effectively

and realize safe construction.

Our ram type blowout preventers (BOPs) are in accordance with API 16A standards for low and high pressure

applications.All components such as the ram block assemblies, pistons, body, pressure seals, flanged or studded

end connections, and bonnets are remanufactured to API standards and are restored to a "like-new" condition.

Our rebuilt Ram BOPs are high quality units sold at a fraction of buying an OEM replacement RAM BOP.

Usages:

The ram blowout preventer is designed to seal off the well bore when drill pipe, casing, or tubing is in the well. In a BOP stack, ram preventers are located between

the annular blowout preventer and the wellhead. There are typically 3 or 4 ram preventers in a BOP stack. Flanged or hubbed side outlets are located on one or both sides

of the ram BOPs. These outlets are sometimes used to attach the valved choke and kill lines to. The outlets enter the wellbore of the ram preventer immediately

under the ram cavity. Other than sealing off the well bore, rams can be used to hang-off the drill string.

A pipe ram, closed around the drill pipe with the

tool-joint resting on the top of the ram, can hold up to 600,000 lbs. of drill string.

Category:

1. Classified as per ram quantity: Single ram blowout preventer; Double ram blowout preventer; Triple ram blowout preventer;

2. Classified as per ram shape:

Blind Rams: The rubber sealing element is flat and can seal the wellbore when there is nothing in it

Pipe Rams: The sealing element is shaped to fit around a variety of tubulars, which include production tubing, drill pipe, drill collars, and casing that will seal off the wellbore around it

Variable Bore Rams: The sealing element is much more complex and allows for sealing around a particular range of pipe sizes

Shearing Blind Rams: The blade portion of the rams shears or cuts the drill pipe, and then a seal is obtained much like the blind ram

Specification:

Bore Size: 7 1/16~16 3/4(180mm~680mm)

Working Pressure: 14~140Mpa(2000~20000Psi)

Ram Locking Device

A ram locking device is necessary to be fitted to all ram blowout preventers. This device is used whenever it is necessary to remove hydraulic operating pressure

from the "close" side of the ram operating system, but maintain the ram preventer in the close position. On BOP stacks that are used in a surface application, the ram

locking device is a threaded rod, referred to as a "lock screw". This lock screw reacts between the operating piston in the ram operating system, and the housing of the lock screw.

The locking device on a ram preventer that is used in a subsea application must be designed to be remotely actuated by either the BOP hydraulic control unit, or by the actual movement of the operating piston in the ram operating system.

Company Introduction

XI'AN KINGWELL OILFIELD MACHINERY Co., Ltd. (KINGWELL) is a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provides complete solutions.

With over 10 years developing, we were developed from the beginning drilling service to manufacture factory who produce OCTG, drilling tools, DST tools and Solid control products.

KINGWELL have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation; our aim is to build solid relationship with any part of honest. kingwell can provide highly efficient services to its clients resulting in accurate and timely deliveries at the best prices. Our products have been exported to Europe, American and Middle East.

.jpg)

.jpg)