|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

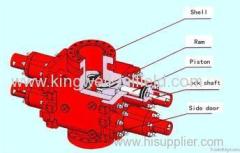

API Annular Blowout Preventor

| Price: | 10.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The annular BOP is used to seal off a well where the drill pipe is in use if the well blows out. However,the annular BOP cannot be closed for long ti

1,Application:

Used in conjunction with hydraulic control system,

the annual BOP seals off the annulus of different sizes when pipes are in use in

the hole. An annular BOP can also seal off the hole when no pipe is in it. When

used in conjunction with the pressure-regulating valve and accumulator, the

annular BOP allows snubbing service.

2,Working

Principles:

A hydraulic control system is used to close or open the

annular preventer. When it is closed, high pressure oil is directed to the

closing chamber positioned in the lower side of the piston, causing the piston

to move upward. The packing unit is compressed by the moving piston. Because the

annular BOP has a cap, the packing unit can not move upward an only can move

toward the center of the well to pack off a string or seal off the well.

3, Operating Requirements:

A, The annular BOP can be used to

seal off a well where the drill pipe is in use if the well blows out. However,

the annular BOP cannot be closed for a long time, because the packing unit is

easy to be damaged and the BOP itself has no lacking mechanism.

B,It is

necessary to use a drilling tool with 18°bevel when running/retrieving drill of

operation with BOP, running/retrieving drill should be slow pass through the

nipple and all the rubber protecting collar on the drilling tool should be

discharged off.

C,With the annular BOP in the closed position and shut-in

pressure kept below 5MPa,the string can be moved either up or down, but mustn't

be rotated.

D, It is forbidden to open the annular BOP to relieve the

pressure out of the well to avoid rubber core damage.

E, Be sure to check

whether the annular BOP is in the full open position or not every time after

opened in order to prevent damage to the packing unit.

F, Clean the inside of

the BOP after well cementing operation is completed in order to keep its

closings and openings flexible.

G, More attention shall be paid to ring

gaskets and gasket grooves during installation of the BOP or its removal from

the service.

H, After entering the destination layer, running/retrieving

drill once should be accompanied with test of well enclosed with drilling tool

once, and inspect the effect of well enclosed with rubber core, if beyond the

requirement, it should be replaced.

I, Periodically perform pressure test on

the annular BOP in accordance with applicable standards.

1. Cap 2.Packing

Unit

3.Support Ring 4.Piston 5.Body

4. Tapered

Rubber Annular BOP

1,Upper housing and the body have two

connection forms as connection by bolts and connection by claw chuck.

2,Annular BOP with tapered rubber is composed of seven parts as upper

housing, wear plate, body, piston, tapered rubber, anti-dust ring supporting

cylinder.

3,The dynamic seal of annular BOP adopts the sealing ring of lip

structure, which reduces the wearing of sealing ring to maximum, and the sealing

is reliable; the rubber is not easy to fold back, and there is the effect of

funnel; and the well pressure has the function of assisting sealing, etc.

5. Spherical

Rubber Annular BOP

1,Upper housing and the body have two

connection forms as connection by bolts and connection by claw chuck.

2,Annular BOP with tapered rubber is composed of five parts as upper

housing, body, piston, spherical rubber and anti-dust ring.

3,The dynamic

seal of annular BOP adopts the sealing ring of lip structure, which reduces the

wearing of sealing ring to the maximum, and the sealing is reliable; the rubber

is not easy to fold back, and there is the effect of funnel; and the well

pressure has the function of assisting sealing , etc.

6. Specifications And Technical Parameters Of Model A Annular BOP

Model | (mm) Bore | (Mpa/psi) Working pressure | Dimensions(mm) | Opening oil volume | Closing oil volume | |

FHZ18-70 | 179.4 | 70/10000 | 1200 | 1250 | 27 | 36 |

2FHZ28-70 | 279.4 | 70/10000 | 1465 | 1653 | 66 | 67 |

FHZ35-70 | 346.1 | 70/10000 | 1554 | 1742 | 117 | 116 |

FHZ43-35 | 425.4 | 35/5000 | 1680 | 1590 | 134 | 134 |

FHZ54-14 | 539.7 | 14/2000 | 1380 | 1437 | 94.5 | 95.3 |

.jpg)

.jpg)