|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

API 16A BOP Annular and Ram Blowout Preventer

| Price: | 10000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Ram type: Bore Size:7 1/16~16 3/4(180mm~680mm)14~140Mpa(2000~20000Psi)

Annular Type: Bore Size:7 1/16~21 1/4 3/4(180mm~540mm)14~105Mpa (2000~15000psi

General Introduction:

A blowout preventer is a large, specialized valve or similar mechanical device, usually installed redundantly in stacks, used to seal, control and monitor oil and gas wells.

In addition to controlling the downhole (occurring in the drilled hole) pressure and the flow of oil and gas, blowout preventers are intended to prevent tubing

(e.g. drill pipe and well casing), tools and drilling fluid from being blown out of the wellbore (also known as bore hole, the hole leading to the reservoir) when

a blowout threatens. Blowout preventers are critical to the safety of crew, rig (the equipment system used to drill a wellbore) and environment, and to the

monitoring and maintenance of well integrity; thus blowout preventers are intended to provide fail-safety to the systems that include them.

Most blowout preventer (BOP) stacks contain at least one annular BOP at the top of the BOP stack, and one or more ram-type preventers below.

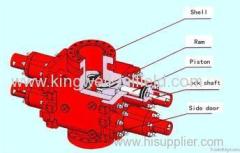

Ram type blowout preventer

Usages:

The ram blowout preventer is designed to seal off the well bore when drill pipe, casing, or tubing is in the well. In a BOP stack, ram preventers are located

between the annular blowout preventer and the wellhead. There are typically 3 or 4 ram preventers in a BOP stack. Flanged or hubbed side outlets are

located on one or both sides of the ram BOPs. These outlets are sometimes used to attach the valved choke and kill lines to. The outlets enter the wellbore

of the ram preventer immediately under the ram cavity. Other than sealing off the well bore, rams can be used to hang-off the drill string. A pipe ram,

closed around the drill pipe with the tool -joint resting on the top of the ram, can hold up

to 600,000 lbs. of drill string.

Category:

1. Classified as per ram quantity: Single ram blowout preventer; Double ram blowout preventer; Triple ram blowout preventer;

2. Classified as per ram shape:

Blind Rams: The rubber sealing element is flat and can seal the wellbore when there is nothing in it

Pipe Rams: The sealing element is shaped to fit around a variety of tubulars, which include production tubing, drill pipe, drill collars, and casing that will seal off the wellbore around it

Variable Bore Rams: The sealing element is much more complex and allows for sealing around a particular range of pipe sizes

Shearing Blind Rams: The blade portion of the rams shears or cuts the drill pipe, and then a seal is obtained much like the blind ram

Specification:

Bore Size: 7 1/16~16 3/4(180mm~680mm)

Working Pressure: 14~140Mpa(2000~20000Psi)

Annular Blowout Preventer

Usages:

When there is no drilling tool in hole, it can seal the wellhead completely.

It can seal any size of annular space with a kind of rubber if there is a drilling tool, tubing or casing in hole.

When the well blowout and overflow happens during drilling, coring or well logging, it can seal the annular spaces between Kelly, coring tools, cable, wireline and wellbore.

Under the control of the hydraulic control system which is equipped with a depressuring pressure regulating valve or a cushion accumulator, it can force stripping with 18°tool joint.

Category

Annular BOP using the spherical packing element

Annular BOP using the conical packing element

Annular BOP using the Combined packing element

Specification

Bore Size: 7 1/16~21 1/4 3/4(180mm~540mm)

Working Pressure: 14~105Mpa(2000~15000Psi)

.jpg)

.jpg)