|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

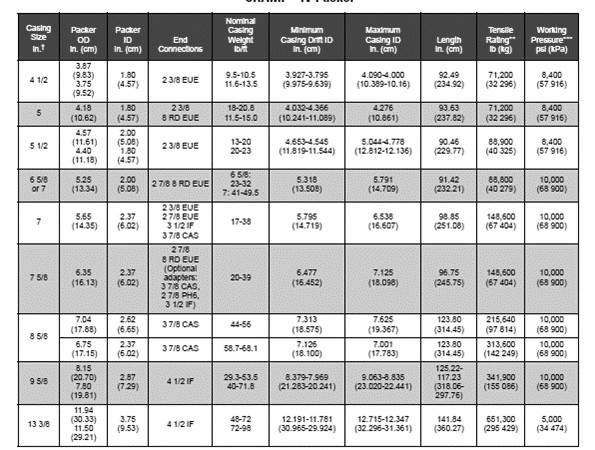

DST Tools 3 7/8" CHAMP IV Packer

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

product model:CHAMP V Packer,CHAMP IV Packer

Operate: ANNULAR PRESSURE OPERATED

Working condition: High pressure high temperature(HPHT)

Size:3 7/8"

DST(Drill Stem Testing) Tools 3 7/8" CHAMP IVPacker

Working pressure: 10000psi ~ 15000psi

Size: 3 7/8"

Standard: NACE MR0175

Operate: ANNULAR PRESSURE OPERATED

Working condition: High pressure high temperature(HPHT)

Type: full bore drill stem testing

Application: oil well testing

Product model:CHAMP Packer High Pressure High Temperature

CHAMP V Packer,CHAMP IV Packer

Service:H2S, CO2

Briefly Introduce:

The CHAMP IVpacker is a hookwall-retrievable packer with a concentric bypass. As the tool is lowered into the hole, a J-slot holds the bypass open and controls the setting of the packer. When the packer is set, a balancing piston activated by tubing pressure holds the bypass closed.

Each tool assembly includes a J-slot mechanism, mechanical slips, packer elements, hydraulic slips, and a bypass. Round, piston-like slips used in the hydraulic holddown mechanism prevent the tool from being pumped up the hole. The bypass allows fluids to pass around the bottom of the tool when it is removed from the hole. This design eliminates accidentally openingconventional bypass during circulation around the bottom of the packer.

Circulation around the CHAMP IV packer is not interrupted if the packer element temporarily seals unintentionally as when it passes through points of interference in the casing.

The CHAMP IV packer is well suited to tubing conveyed perforating applications where the firing head assembly is easily incorporated into the CHAMP IV packer. The CHAMP IV packer is ideally suited for horizontal applications due to its limited rotational requirements and integrated circulating valve. Just a quarter-turn is required, at the tool, to set the packer and close the circulating valve. A straight upward pull opens the circulating valve and unseats

the packer.

Features and Benefits

• The packer is used in highly deviated wells or where pipe manipulation is difficult.

• Picking the packer straight up (no torque required) opens the bypass.

• The tool is easily relocated in multiple zones during a single trip for treating, testing, or squeezing.

• The concentric bypass valve allows a larger bypass flow area.

• The CHAMP IV packer is used with a retrievable bridge plug for straddling zones during various operations.

• A CHAMP IV packer would be the tool of choice where positive circulation below the packer is required such as

in drillstem testing, TCP applications, using tailpipe, for shallow service, and as liner tools.

Operation

The tool is run slightly below the necessary setting position. If the packer is to be set, it must be picked up, and right-hand rotation must be applied so that a half-turn can be obtained at the tool. In deep or deviated

holes, several turns with the rotary may be necessary. For the position to be maintained, the right-hand torque must be held until the mechanical slips on the tool are set and can begin taking weight.

Pressure applied below the packer forces the hydraulic holddown slips against the casing to prevent the packer from being pumped up the hole.

The concentric bypass valve is balanced to the tubing surface pressure, which prevents the bypass from being pumped open with tubing pressure. Straight, upward pull on the tubing string opens the bypass and unsets the packer.

Specifications:

1. Halliburton type, all could change with Halliburton parts.

2. All equipments are produced according to API standard NACE MRO175-2002

Below are specfor you reference:

Company Introduction

Xi'an Kingwell Oilfield Machinery Co.,Ltd is a professional supplier for oilfield products according to the API standard.

Our products have exported to USA, Canada, Egypt, India and UEA, etc with 40 FCL containers per month. Now, with high quality and short supply and good service, our products have got good reputation home and abroad .

Here we got some prise as follows.

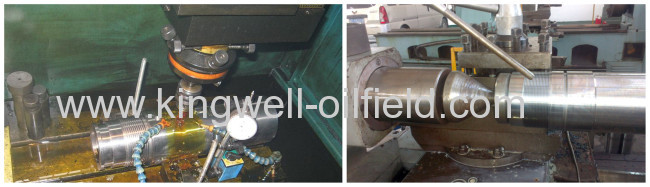

Manufacturing Facility

Equipped with latest machining facilities like CNC 3-axis Turning centers, CNC 4-axis milling centre, high temperature heat treatment furnaces, Centre lathe machines, Deep Hole Drilling, Boring & Honing machines, our company could meet long term production target and be governed efficiently by well-qualified and experienced Board of Directors and Engineers.

The following is the manufacturing workshop.

Quality Systems

A well-established Quality System from Materials receipt to Products delivery ensures consistent quality at all levels of the activity. QMS Procedures & Measurements are tailored to establish high standards of Quality Assurance in the Operations. The Company maintains the 100% Traceability records as per API requirements &NACE MR 0175-2002 Standards and complies with all the legal, statutory and regulatory requirements.

1\Quality control of the raw material:

1)The selection of the raw material supplier:our raw materials mainly include alloy structural steel, stainless steel, non-ferrous metal alloy and high nickel alloy, etc, in the selection of the raw material suppliers, we would do the comprehensive assessment of the supplier strictly according to technical requirements .Most of our suppliers are the leading enterprises of the steel production in China and the special alloy are usually purchased from abroad to ensure a higher mechanical properties.

2) The acceptance & Inspection of the raw material:

Ultrasonic flaw detection for every piece of the steel.

Chemical composition analysis for every piece of the steel.

Mechanical performance test for every piece of the steel..

2\Quality control of the seals:

1) O Rings: 100% visual and dimensional inspection for every piece of the O-rings, 15% spot check for the size and hardness test of the o rings. As for the sealing and heat resistance properties of the o rings, we designed a special test device which is equipped with heating insulation equipment that can simulate the down hole temperature and pressure. At present, our fluorine can keep a good performance in the condition of 210 ℃, and 105 Mpa work pressure (maximum pressure ever reached 146).

2) Back-up ring: 100% visual and dimensional inspection for every piece of the back-up ring, as for the test of the sealing and heat resistance, we design and manufacture the special test device, equipped with heating insulation equipment to stimulate the down hole temperature and pressure for acceptance. At present, our company's high pressure back-up seal can keep good sealing performance and deformed a little in the condition of 210 ℃, and 105Mpa work pressure (maximum pressure ever reached 146). It can be used for many times.

3. Quality control of the spring: Apart from the conventional test of the raw material and size of the different springs that used in the tools, we specially designed a test device that equipped with heating preservation equipment to stimulate the down hole temperature and condition to test the spring performance.

4. Quality control of the spare parts processing:

1) Spare parts processing control:In strict accordance with the process and traceability requirements, a test, mark and record of dimension, geometric tolerance and for every piece and every procedure will be conduct.

2) Heat treatment quality control: We have two high temperature heat treatment furnaces that are mainly used for stainless steel and other special material heat treatment. For other materials, we entrust Baoji Petroleum Machinery Company Heat Treatment Plant to do the heat treatment.For the inspection of the heat treatment, we are equipped with the special inspection machine such as gantry hardness tester, digital universal tensile tester etc.

5. Quality control of the tool assembly and testing process

1) Test equipment: in addition to the conventional hydraulic test pump, tensile testing machine, we also have a pressure sensor and data acquisition system which can accurate and clear record each step of the test.

2) Technical documents: We have a test acceptance list for every tool test that clearly guides the each step of the test.

3) Assembly test: A special inspector will supervise the whole assembly process.

The following is the picture of Product Processing

Related products

We also provide accessories and other related products, which you can find in this website.

The following is the pictures about related products.

Service

Kindly let me know if you have any interest or enquiry about our products. You are also always welcomed to come to our factory for a visit at your convenient time.

We will offer you a good price and show you our best service.