|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

DST(Drill Stem Testing) Tools 16" RTTS Packer

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

size:16"

Working pressure: 10000psi ~ 15000psi

product model:DST tools 16" RTTS Packer

Application:Drill Stem Testing

Service:H2S,

Standard:API

DST tools 16" RTTS Packer

Application:Drill Stem Testing

Size:16"

Working pressure: 10000psi ~ 15000psi

product model:DST tools 16" RTTS Packer

Application:oil well testing

Service: H2S, CO2

Usage: Offshore Oil and Gas Field Exploitation Machinery

Type: Petroleum Drilling Tool & Accessory

Condition: New

Working condition: High pressure high temperature(HPHT)

Briefly Introduce:

The RTTS packer is a full-opening, hookwall packer used for testing, treating, and squeeze cementing operations. In most cases, the tool runs with a circulating valve assembly.

The packer body includes a J-slot mechanism, mechanical slips, packer elements, and hydraulic slips. Large, heavy-duty slips in the hydraulic holddown mechanism help prevent the tool from being pumped up the hole. Drag springs operate the J-slot mechanism on ≤ 3 1/2-in. (88.9-mm) packer bodies, while larger packer sizes ≥ 4-in. (101.6 mm) use drag blocks. Automatic J-slot sleeves are standard equipment on all packer bodies.

The circulating valve, if used, is a locked-open/locked-closed type that serves as both a circulating valve and bypass. The valve automatically locks in the closed position when the packer sets. During testing or squeezing operations, the lock prevents the valve from being pumped open. A straight J-slot in the locked-open position matches with a straight J-slot (optional) in the packer body. This combination eliminates the need to turn the tubing to close the circulating valve or reset the packer after the tubing has been displaced with cement.

Features and Benefits

• The full-opening design of the packer mandrel bore allows large volumes of fluid to pump through the tool. Tubing-type guns and other wireline tools can be run through the packer.

• The packer can be set and relocated as many times as necessary with simple tubing manipulation.

• Tungsten carbide slips provide greater holding ability and improved wear resistance in high-strength casing. Pressure through the tubing activates the slips in the hydraulic holddown mechanism.

• An optional integral circulating valve locks into open or closed position during squeezing or treating operations, and opens easily to allow circulation above the packer.

Operation

The tool is run slightly below the desired setting position to set the packer and is then picked up and rotated several

turns. If the tool is on the bottom, only a half-turn is actually required. However, in deep or deviated holes, several turns with the rotary may be necessary. To maintain position, theright-hand torque must be held until the mechanical slips on the tool are set and can start taking weight The pressure must be equalized across the packer to unset it. As the tubing is picked up, the circulating valve remains closed, establishing reverse circulation around the lower end of the packer. The circulating valve is opened for coming out of the hole when the tubing is lowered, rotated to the right, and picked up.

Specifications:

1.Halliburton type, all could change with Halliburton parts.

2.All equipments are produced according to API standard.

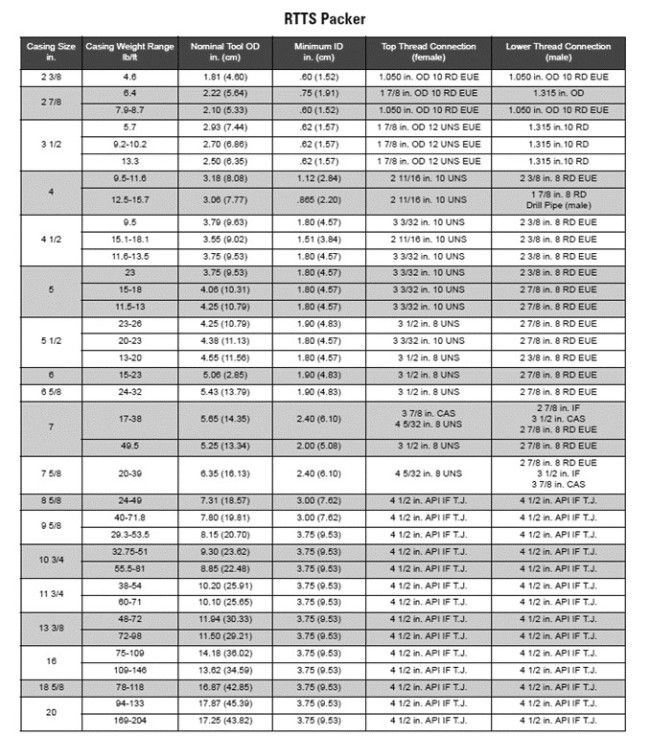

Below are specfor you reference:

Certifications

Kingwell is a CNPC & SINOPEC & BV certified company, having all the Quality Systems in place for design, planning, manufacturing and quality monitoring & traceability to ensure our products match the highest quality standards.

We test our products strictly according to the NACE MR 0175-2002 Standard and our quality assurance period is 12 months.

Certificates endorsed by DNV/BV/ABS and Documents we can supply with the shipments:

1. Pressure Test Certificate with Graph and time recorded.

2. Function Test

3. Rubber Products NACE Compliance

4. Material Mill Certificate and treatment characteristics

5. H2S Compliance

6. Service Manual

7. Parts Manual

8. Testing Procedures.

9. Open up type tool drawing for dressing purpose– if any.

Design & Development

Kingwell has an ongoing relationship with Xi'an Petroleum University and built up long term cooperation with China Aerospace Group for more than 10 years. Design Department is familiar with CAD and Pro-E facilities and has on rolls qualified & experienced engineers. Now, they are engaged in development of new products as required in the market place. Kingwell' products are validated in-house in a Test Well, a Sub-surface Type Test Facility with simulated well conditions up to 15000 psi Differential pressure , 400°F and Max 450°F.

Manufacturing Facility

Equipped with latest machining facilities like CNC 3-axis Turning centers, CNC 4-axis milling centre, high temperature heat treatment furnaces, Centre lathe machines, Deep Hole Drilling, Boring & Honing machines, our company could meet long term production target and be governed efficiently by well-qualified and experienced Board of Directors and Engineers.

Related products

We also provide accessories and other related products, which you can find in this website.

The following is the pictures about products accessories and some other related products

Product delivery

Payment:TT/LC:30% advance payment.70%before shipment

Warranty: Warranty period is 1 year after installation.

Origin: China

Minimum order: 1 set

Packaging: wood case or steel carton

Delivery Date: within 1-2 month(s) after receiving prepayment

Logo: KW, we can produce according to customer requirements.

Technical Documents: We can provide technical documents according to your requirements.

Additional service: Customers are served to test our products in our factory upon request.

Service

Kindly let me know if you have any interest or enquiry about our products. You are also always welcomed to come to our factory for a visit at your convenient time.

We will offer you a good price and show you our best service.

.jpg)