|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

API Mud Pump Liner from KINGWELL

| Price: | 100.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Kingwell can supply all kinds of API Standard Mud pump liner with different size and top grade quality and interchange with other brands.

1. Specifications:

Mud Pump Liner with different Size

1). Material:Forged steel

2). High quality and long work time

3). Liners for mud pump parts

4). Our products can interchange with the mud pump produced by BOMCO, RG, HH and LS.

5). Small Minimum Order.

6). Quick delivery as we have some stocks in warehouse

7). Good service

2. API Std. Mud Pump Liner for Oil Drilling

A cylinder liner ( or cylinder sleeve) is a cylindrical part to be fitted into an engine block to form a cylinder. It is one of the most important functional parts to make up the interior of an engine. Our products after quenching technology for the surface and heat treating, the forged liner is with high intensity, strong tenacity and wearability. Main functions as belows:

(1) Formation of sliding surface

The cylinder liner, serving as the inner wall of a cylinder, forms a sliding surface for the piston rings while retaining the lubricant within. The most important function of cylinder liners is the excellent characteristic as sliding surface and these four necessary points.1) Less wear on the cylinder liner itself2) Less wear on the partner piston ring 3) Less consumption of lubricant

(2) Heat transfer

The cylinder liner receives combustion heat through the piston and piston rings and transmits the heat to the coolant.

(3) High temperature and high pressure

A cylinder wall in an engine is under high temperature and high pressure, with the piston and piston rings sliding at high speeds. In particular, since longer service life is required of engines, forging cylinder that have excellent wear-resistant properties are only used for cylinder parts.

We can provide the following liners: GARDNER DENVER: PZ-7, PZ-8, PZ-9, PZ-10, PZ-11;

IDECO: T–500, T–800, T–1000, T–1300, T–1600

3. Detailed description:

The Kingwell Mud pump liners used for mud pumps include premium Chromium Liners, Ceramic Liners, Chromium-plated Liners and Hardened Liners. Each liner combine the strength of a forged steel outer shell with the abrasionand corrosion resistance of a high chromium iron inner sleeve and honed to a mirror-like finish for smooth and even wear during the of the liner.

4. Parameters:

| EMSCO | |||

| F-350 | F-500 | F-650 | F-800 |

| F-1000 | FB-1300 | FB-1600 | |

| Gardner Denver | |||

| PAH | TEE | PZ-7 | PZ-8 |

| PZ-9 | PZ-10 | PZ-11 | |

| IDECO | |||

| T-500 | T-800 | T-1000 | T-1300 |

| T-1600 | |||

| National | |||

| 7-P-50 | 8-P-80 | 9-P-100 | 10-P-130 |

| 12-P-160 | JWS165L | ||

| Oilwell | |||

| A-350 | A-560 | A-600 | A-850 |

| A-1100 | A-1400 | A-1700 | |

| Others | |||

| 350-D | 350-DG | 500-DC | 700-HDL |

| 1000-HDL | MAS1000 | ||

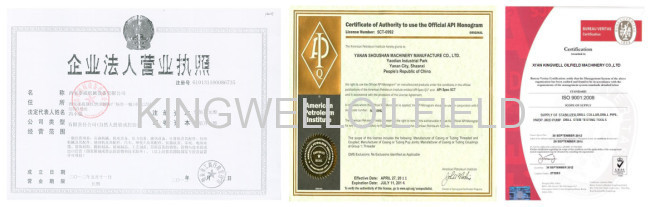

5. Company Introduction:

Xi'an Kingwell Oilfield Machinery Co.,Ltd is a professional supplier for oilfield products according to the API standard. Our products have exported to USA, Canada, Australia, Egypt, India and Uae, etc with high quality and short supply and good service, our products have got good reputation home and abroad .

Kingwell Certificates:

Kingwell top grade mud pump series:

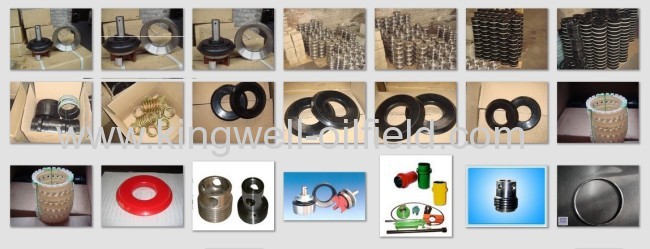

All kinds of Mud pump Liners with different materials:

Other Mud pump spare parts:

Our stocks for the Mud pump spare parts:

6. Manufacturing Facility

Equipped with latest machining facilities. Our company could meet long term production target and be governed efficiently by well-qualified and experienced Board of Directors and Engineers.

The following is the manufacturing workshop.

7. Training and Field Supports

We have a team of well qualified and experienced field support personnel for Training. According to customer's requirements, we provide operation training service for our customers who cooperated with us.

Generally speaking, our customer training mainly includes followings:

1) To know the basic knowledge of the products, such as the usage, the working environments, the working principles, the structure, ect.

2) To learn the operation and use of products.

3) To master the basic requirement of designs of tool strings and of testing operation.

8. Product delivery:

Payment term: 30% deposit by T/T or L/C and 70% before shipment.

Warranty: Warranty period is 12 months after installation.

Origin: China Mainland.

Minimum order: 10 sets

Packaging: wood case or steel frame which suitable for long term transportation.

Delivery Date: within 1-2 month(s) after receiving the deposit.

Logo: KW or customize.

Technical Documents: We can provide technical documents according to your requirements.

Additional service: Customers are served to test our products in our factory upon request.

9. The followings are some pictures about product packaging

10. Service

We believe in Customer delight, achieved by the supply of Quality Products & Services and Continual Improvement in our Manufacturing Processes for timely delivery at competitive prices. We work in a professional, competitive, and cost-effective manner consistent with the Customer requirement

Any interest of above products or relative parts, PLS feel free contact back, and we will offer a good price and show you our best service upon received from you.