|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

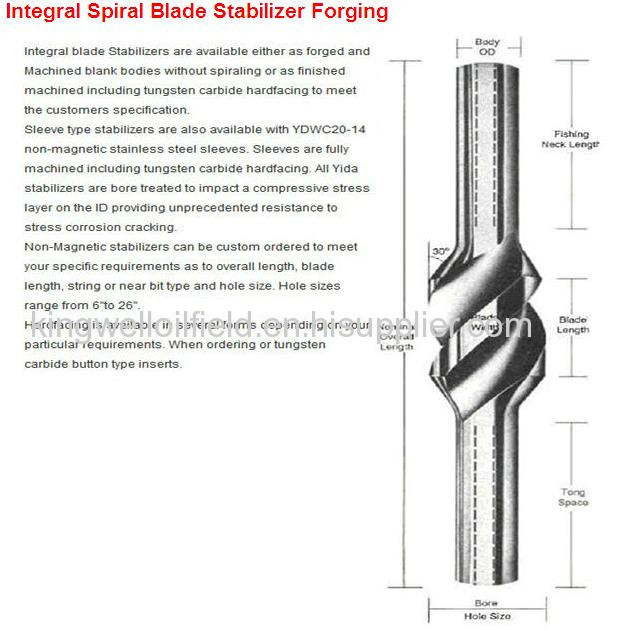

Forging 4145H Mod Oil Drilling Tools Stabilizers

| Price: | 10.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Type: string, near bit

2.Raw material: AISI4145H MOD

3.Standard: API SPEC7-1

4.Forge+Q&T+sprial+API connection+hardfacing

5.6" to 36"

Forging 4145H Mod Oil Drilling Tools Stabilizer

Product Desciption:

API 7-1 finished stabilizer with HF4000

Stabilizer Material: AISI 4145H, AISI 4340, AISI 4140-4142, and Non-magnetic Material.

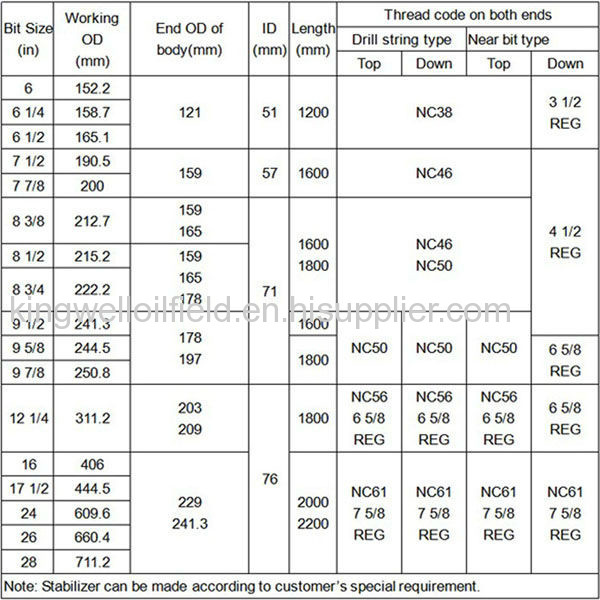

OD of Bits: 6"-28"

Hardfacing for IBS: HF 1000, HF 2000, HF 3000 and TCI

Delivery Condition of semi-finished stabilizer or reamer forgings:

Heat treated by water quenching and tempering, rough machined to drawing dimensions, UT-Tested according to ASTM A-388

Mechanical property requirement:

Tensile Strength 140.000PSI Min

Yield Strength 110.000PSI (0.2% offset)Min

Elongation 13% Min

Reduction of Area 45% Min

CHARPY-V-N 40

Made from AISI 4145 H Modified Alloy Steel. Heat treatedto 285-341 Brinell Hardness and 54 Joules minimum impact value. All physicalproperties would be guaranteed 1" below the surface. All threads are madestrictly in accordance with API 7-1 specification. Qualified to NS-1 Standard.

HARD FACING TYPE:

HF1000Hard facing with Crushed carbide

HF2000Hard facing with Crushed carbide withTrapizoidalinsert

HF3000Hard facing with Tungsten carbide insert set ina powder spray deposit

HF4000Hard facing with Tungsten carbide insert

HF5000 Hard facing with Fused tungsten carbide in nicklechrome boron matrix

Hardfacing we can provide as follows:

HF1000 Crushed tungsten carbide held in a nickel bronze matrix. The 3mm grain size ensures greater concentration of carbide which is ideal for soft formation drilling.

HF2000 Trapezoidal tungsten carbide inserts held in a sintered carbide nickel bronze matrix. This will give a greater depth of carbide coverage -- ideal for high deviation drilling in abrasive formations.

HF3000 Tungsten carbide inserts set in a power spray deposit ideal for abrasive formation. 97% bonding guaranteed, certified by ultrasonic report. Recommended for non-magnetic stabilizers.

TCI Tungsten carbide inserts (button type). The inserts have been developed to allow cold insertion and maintain close fit. A greater concentration of inserts on the bottom third of the blade and leading edge will increase surface contact to reduce wear in highly abrasive formations.

Maching process:

Maching facilities:

Quality test:

About KINGWELL

Xi'an Kingwell Oilfield Machinery Co.,Ltd is a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provide complete solutions.

With over 10 years developing, we were developed from the beginning drilling service supplier to a manufacture who have own factory and specially produce stabilizer, forgings, BOP & spare parts and DST tools products.

We have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation; our aim is to build solid relationship with any part of honest. We can provide highly efficient services to each client resulting in accurate and timely deliveries at the best prices. We sincerely hope to make cooperation and mutual benefit wih any people who are in Oil & Gas industry.

Welcome any of your enqiry!