|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

4145H Mod & Non-magnetic Stabilizer Forging

| Price: | 10.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Standard: API 7-1 or Non-Standards

2. Type: String Type; Near Bit Type

3. Steel Grade: AISI 4145 H; Non-Magnetic

4. Size: Bit (6''---36'')

4145H Mod & Non-magnetic Stabilizer Forging

Specifications:

1. Standard: API 7-1.

2. Type: String Type; Near Bit Type.

3. Steel Grade: AISI 4145 H; Non-Magnetic.

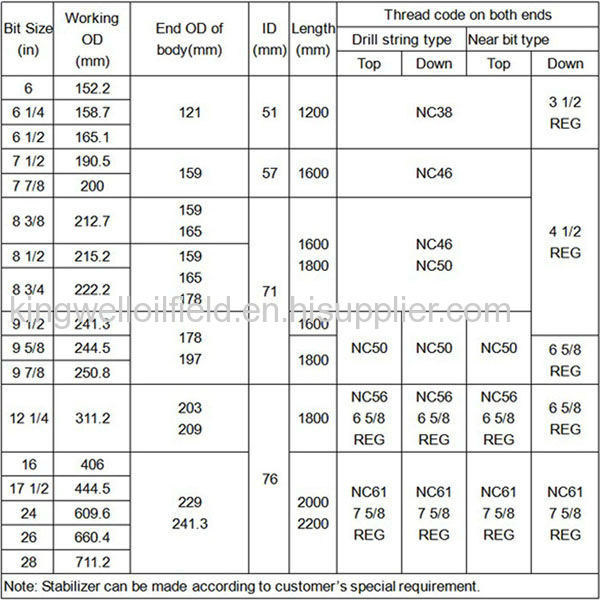

4. Size: Bit (6''---28'') * ID (1 3/4''---3 1/2'') * Length (40').

5. Cold Rolling of Thread Roots

6. Stress Relief Groove

7. Thread Surface Process: Phoscoating or Copperize Process Treatment.

8. Hard Facing Material: Carbide Insert; Diamond Compound Insert; Low Temperature Brazing TungstenCarbide Slug; Surface Bead Welding Abrasive Welding Rod; etc.

9.Cast Steel Thread Protector.

10. Delivery Condition: Forged Bar; Semi-Finished; Finished Stabilizer.

Hardfacing we can provide as follows:

HF1000 Crushed tungsten carbide held in a nickel bronze matrix. The 3mm grain size ensures greater concentration of carbide which is ideal for soft formation drilling.

HF2000 Trapezoidal tungsten carbide inserts held in a sintered carbide nickel bronze matrix. This will give a greater depth of carbide coverage -- ideal for high deviation drilling in abrasive formations.

HF3000 Tungsten carbide inserts set in a power spray deposit ideal for abrasive formation. 97% bonding guaranteed, certified by ultrasonic report. Recommended for non-magnetic stabilizers.

TCI Tungsten carbide inserts (button type). The inserts have been developed to allow cold insertion and maintain close fit. A greater concentration of inserts on the bottom third of the blade and leading edge will increase surface contact to reduce wear in highly abrasive formations.

Detailed description about our stabilizers range:

Kingwell Introduction

Xi'an Kingwell Oilfield Machinery Co.,Ltdis a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provide complete solutions.

With over 10 years developing, we were developed from the beginning drilling service supplier to a manufacture who have own factory and specially produce stabilizer, forgings, BOP & spare parts and DST tools products.

We have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation; our aim is to build solid relationship with any part of honest. We can provide highly efficient services to each client resulting in accurate and timely deliveries at the best prices. We sincerely hope to make cooperation and mutual benefit wih any people who are in Oil & Gas industry.

Training and Field Supports

We have a team of well qualified and experienced field support personnel for Training. According to customer's requirements, we provide operation training service for our customers who cooperated with us.

Generally speaking, our customer training mainly includes followings:

1) To know the basic knowledge of the products, such as the usage, the working environments, the working principles, the structure, ect.

2) To learn the operation and use of products.

3) To master the basic requirement of designs of tool strings and of testing operation.

Product delivery:

Payment term: 30% deposit by T/T or L/C and 70% before shipment.

Warranty: Warranty period is 12 months after installation.

Origin: China Mainland.

Minimum order: 1set

Packaging: wood case or steel frame which suitable for long term transportation.

Delivery Date: within 30 days after receiving the deposit.

Logo: KW or customize.

Technical Documents: We can provide technical documents according to your requirements.

Additional service: Customers are served to test our products in our factory upon request.