|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

Wellhead Equipment Christmas tree Casing and Tubing Spool

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Material Class: AA,BB,CC,DD,EE,FF,HH.

products Class: PSL1-PSL3

Pressure: 2000PSI-20000PSI

Performance Class: PR1, PR2

Temp Range: K,L,N,P,S,T,U,V

API 6A Oilfield Wellhead Equipment Casing and Tubing Spool

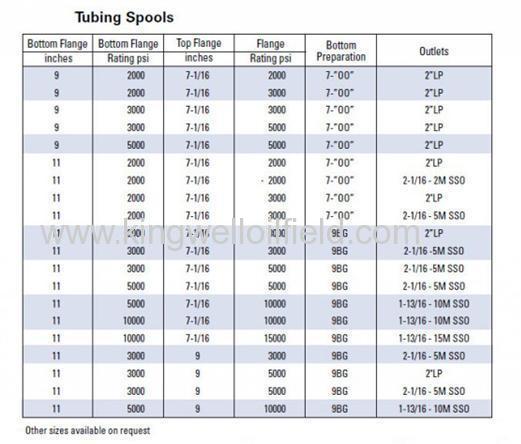

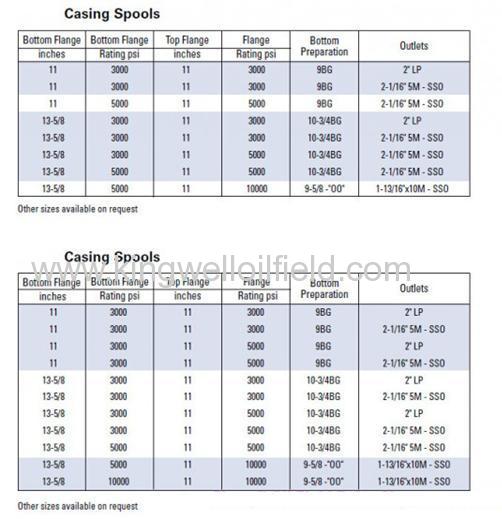

Tubing spool in the wellhead stackup hangs each casing sting after the tubinghead.The bottom prep of the spool has been engineered to contain a packoff seal and flange for either a clamp-hub or a standard flange connection. For annular access, either studded or line pipe outlets can be machined into the spool.The tubing spool has a straight bore bowl with 45°landing shoulder design which avoids damage to sealing areas by drilling tools and prevents test plug and bowl protector wedging problems when pressure is applied.

Features

• Versatile straight-bore design,uses a 45° landing shoulder;

• 3 different types of outlets: Line pipe, Flanged (Studded) Extended flanged outlets.

• Allows use of lock screws to retain hanger.

• Has a additional lock screws for Bowl protecion..

• Accepts a wide variety of slip and mandrel casing hangers.

• Multiple bottom sealing type, such as: PE/BG bottom,OO bottom and double "P" seal bottom.

Manufacturing and inspection

1.Casing Head-Bottom Slip Connection

(1) Connect surface casing by type WD slip.

(2) Adopt type BT secondary seal structure.

(3) Accurately calculate casing string's length is not necessary.

(4) Can not be affected by surrounding environment, climate, etc.

(5) Easy, rapid, safe and reliable in installation.

(6)Can apply to different sizes casing, such as: 30",20",13-3/8",12-1/4",9-5/8",7",5-1/2".

(7)We can manufacture a variety of bottom thread such as CSG, LCSG, BCSG, TM, for the connection between casing head and surface casing.

2. Casing Head-Bottom thread connection

(1)Bottom of the casing head connects surface casing by various types of threads,such as CSG,LCSG,BCSG,TM,ETC.

(2)Convenience and rapid in installation,safe and reliable in operation.

3. Casing Head-Bottom welded connection

(1)Bottom of the casing head connects surface casing by welding.

(2)There's pressure test hole, which can test welding effect, in welding annular space.

(3)Bottom can be connected to surface casing by the method of sleeve welding.Pressure testing holes are designed for the test of welding effect

Brief introduction

1. We can supply various kinds of wellhead equipment, such as tubing head, tubing spool etc.

2. We have rich experience in API 6A,AISI 4130, AISI4140, AISI 4330, AISI4340, AISI 8620, etc.

3. According to customers' requirements, we can choose ESR ingot material so that many mechanical properties can be improved. We can ensure that P/S content is lower than 0.010%, H content lower than 1.8 PPM.

4. We have a series of inspection equipments and test appliances, including chemical analysis, metallographic analysis, mechanical property test, charpy impact test, ultrasonic test, magnetic particle test, etc.

5. We own a series of machining facilities and can finish final machining according to customers' requirements.

Company Introduction

Xi'an KINGWELL OILFIELD MACHINERY Co., Ltd. (KINGWELL) is a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provides complete solutions.

With over 10 years developing, we were developed from the beginning drilling service to manufacture factory who produce OCTG, drilling tools, DST tools and Solid control products.

KINGWELL have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation; our aim is to build solid relationship with any part of honest. kingwell can provide highly efficient services to its clients resulting in accurate and timely deliveries at the best prices. Our products have been exported to Europe, American and Middle East.