|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

Oil Field Using Square Kellys Square Kelly

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.API Spec Kelly

2.4145H or Non-magnetic steel

3.strict quality assurance

4.competitive price

Forged Oil Field Using Square kelly square kelly

It is mainly used between the drill head and the drill pipe, so that it can make the drill head work reposefully and keep right trace by providing

the pressure and weight for drill head.

Xinhua Forgings mainly include: Drill tools, stabilizers, Forged mill rollers,Forged shafts,Forged bars, round hollow bars,Forged piston, Forged cylinders,Forged Rring&discs,Pipe Mold,etc.

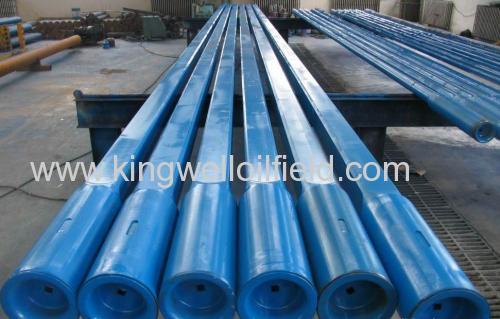

Forged Oil Field Using Round Drill Collar

It is the round pipe with smooth surface and thick wall, and the both ends are machined screw thread for connection.

| Material: | Non-magnetic Alloy steel |

| Processing Type: | Forging |

| Use: | It is mainly used between the drill head and the drill pipe, so that it can make the drill head work reposefully and keep right trace by providing the pressure and weight for drill head. |

| OD: | 79.4 - 279.4 mm |

| Manufacture technique: | Hot forged and heat treated |

| Test: | UT&MT test |

| Length: | 9150 or 9450 mm |

| Connection: | NC23-31,NC31-41,NC35-47,NC38-50,NC44-60,NC50-70,7 5/8REG, 8 5/8REG |

| Test reports | Chemical Composition, Physical Properties and Mechanical Testing according to the customer's requirement |

| Surface finishes: | Black, Peeled, Turned & Polished |

| Delivery condition: | Hot forged, Heat-treatment (Normalized / Annealed / Quenched / tempered), Rough machining. |

| Process: | EAF + LF + VD +(ESR) + Forged + Heat Treatment (optional) |

material of non-magnetic drill collars | Non magnetic steel |

| Standard: | API Spec 7-1 or SY/T5144 Standard. |

| Connections | OD | ID | Length | Bevel Diameter Df mm | Reference Bending Strength Ratio | ||

| mm | in | mm | in | mm | |||

| NC23-31 | 79.4 | 3 1/8 | 31.8 | 1 1/4 | 9150 | 76.2 | 2.57:1 |

| NC26-35 | 88.9 | 3 1/2 | 38.1 | 1 1/2 | 9150 | 82.9 | 2.42:1 |

| NC31-41 | 104.8 | 4 1/8 | 50.8 | 2 | 9150 or 9450 | 100.4 | 2.43:1 |

| NC35-47 | 120.7 | 4 3/4 | 50.8 | 2 | 915 or 9450 | 114.7 | 2.58:1 |

| NC38-50 | 127 | 5 | 57.2 | 2 1/4 | 9150 or 9450 | 121 | 2.38:1 |

| NC44-60 | 152.4 | 6 | 57.2 | 2 1/4 | 9150 or 9450 | 144.5 | 2.49:1 |

| NC44-60 | 152.4 | 6 | 71.4 | 2 13/16 | 9150 or 9450 | 144.5 | 2.84:1 |

| NC44-62 | 158.8 | 6 1/4 | 57.2 | 2 1/4 | 9150 or 9450 | 149.2 | 2.91:1 |

| NC46-62 | 158.8 | 6 1/4 | 71.4 | 2 13/16 | 9150 or 9450 | 150 | 2.63:1 |

| NC46-65 | 165.1 | 6 1/2 | 57.2 | 2 1/4 | 9150 or 9450 | 154.8 | 2.76:1 |

| NC46-65 | 165.1 | 6 1/2 | 71.4 | 2 13/16 | 9150 or 9450 | 154.8 | 3.05:1 |

| NC46-67 | 171.4 | 6 3/4 | 57.2 | 2 1/4 | 9150 or 9450 | 159.5 | 3.18:1 |

| NC50-67 | 171.4 | 6 3/4 | 71.4 | 2 13/16 | 9150 or 9450 | 159.5 | 2.37:1 |

| NC50-70 | 177.8 | 7 | 57.2 | 2 1/4 | 9150 or 9450 | 164.7 | 2.54:1 |

| NC50-70 | 177.8 | 7 | 71.4 | 2 13/16 | 9150 or 9450 | 164.7 | 2.73:1 |

| NC50-72 | 184.2 | 7 1/4 | 71.4 | 2 13/16 | 9150 or 9450 | 169.5 | 3.12:1 |

| NC56-77 | 196.8 | 7 3/4 | 71.4 | 2 13/16 | 9150 or 9450 | 185.3 | 2.70:1 |

| NC56-80 | 203.2 | 8 | 71.4 | 2 13/16 | 9150 or 9450 | 190.1 | 3.02:1 |

| 6 5/8REG | 209.6 | 8 1/4 | 71.4 | 2 13/16 | 9150 or 9450 | 195.7 | 2.93:1 |

| NC61-90 | 228.6 | 9 | 71.4 | 2 13/16 | 9150 or 9450 | 212.7 | 3.17:1 |

| 7 5/8REG | 241.3 | 9 1/2 | 76.2 | 3 | 9150 or 9450 | 223.8 | 2.81:1 |

| NC70-97 | 247.6 | 9 3/4 | 76.2 | 3 | 9150 or 9450 | 232.6 | 2.57:1 |

| NC70-100 | 254 | 10 | 76.2 | 3 | 9150 or 9450 | 237.3 | 2.81:1 |

| 8 5/8REG | 279.4 | 11 | 76.2 | 3 | 9150 or 9450 | 266.7 | 2.84:1 |

| OD. | Yield strength | Tensile strength | Elongation | Brinell Hardness HB | Charpy impact energy | |

| σ0.2 | σb | δ4 | Ak | |||

| mm | in | MPa | MPa | % | J | |

| 79.4~171.4 | 3 1/8~6 3/4 | ≥758 | ≥965 | ≥13 | ≥285 | ≥54 |

| 177.8~279.4 | 7~11 | ≥689 | ≥930 | |||

Steel material standard: ASTM,AISI DIN, BS, CA, AS, ISO and GB standard.

Customers put forward material requirement, mechanical properties and tolerance, maybe full set of engineering Drawing, designing requirement, then our manufacturer will termwise check drawings scrupulously and completely understand technical parameter.There'll be once or twice technical exchange between both parties, or any ameliorating. Everything is ready, next to manufacturing, acceptance and delivery.

We are looking forward to your inqury with detailed requirements.

.jpg)