|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

5-7/8"-28" Drill Jar for well drilling

| Price: | 10.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1 Drilling Jar is a downhole tool

2.API 7-1 certificate

3.with high quality and short supply delivery time

1 Drilling Jar is a downhole tool

2.API 7-1 certificate

3.with high quality and short supply

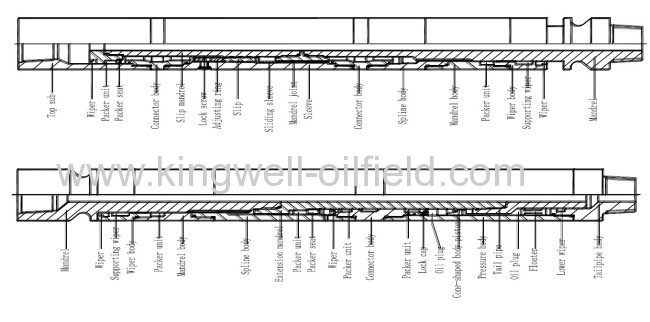

2. Main construction and working principle

The drilling (up ) jar is as shown in block drawing enclosed. and the drilling (down )jar is shown in block drawing enclosed. 2.1 The working principle for drilling (up) jar The up jarring action is obtained by cone body, by-pass body , sealing body and oil seal of sealing body. When jarring is required , lower steadily drill string , move down the mandrel of up jar, cone-shaped piston departs from sealing body, the hydraulic oil between cone body and floater in the cylinder flows into pressure chamber through by-pass body. When mandrel shoulder touches against the end-face of wiper body, the tool is closed. Continuous elevate drill string , the passage between sealing body and lower end of cone body is closed. On two oil discharge grooves can allow a few of oil flowing in, the other oil flowing are blocked at upper part of cone body so that oil pressure is rising and drill string above mandrel gradually stretch to store energy. Because the oil flow limitedly through the oil metering groove on the cone , the drill string extends. When cone body moves up to unload groove, the high pressure oil in pressure chamber in short time release energy. The drill string stretched suddenly

2

shrinks so that top face of extension mandrel strikes against shoulder of spline with extreme high speed and provides a violent up jarring impact against the stuck drill string connected at lower part of external barrel. Steadily elevating the drill tool by several times can force tool to produce continuous up jarring

3.

Up jarring test data

Type | ZSJ80 | ZSJ76 | ZSJ70 | ZSJ62 | ZSJ56 | ZSJ46 |

Rated release force(KN) | 400~600 | 400~600 | 350~550 | 300~450 | 200~350 | 150~250 |

Down jarring test data

Type | ZXJ80 | ZXJ76 | ZXJ70 | ZXJ62 | ZXJ56 | ZXJ46 |

Max.release force(KN) | 600 | 600 | 550 | 500 | 400 | 250 |

Technical specifications and parameters

Type | ZSJ 80 | ZSJ 76 | ZSJ 70 | ZSJ 62 | ZSJ 56 | ZSJ 46 | |

Parameters | ZXJ 80 | ZXJ 76 | ZXJ 70 | ZXJ 62 | ZXJ 56 | ZXJ 46 | |

Item | |||||||

O.D.(mm) | 203 | 197 | 178 | 160 | 146 | 121 | |

I.D(mm) | 71.4 | 71.4 | 70 | 57 | 57 | 51 | |

Pull down | Up | 5515 | 5515 | 5424 | 5360 | 5730 | 5270 |

overall length | |||||||

(mm) | Down | 5250 | 5250 | 5215 | 5208 | 5000 | 5125 |

Pull down | Up | 368 | 368 | 344 | 344 | 332 | 305 |

stroke(mm) | Down | 178 | 178 | 178 | 178 | 180 | 178 |

Thread conn. API | 6 5/8"REG | 6 5/8"REG | NC50 | NC46 | 6 5/8"REG | NC38 | |

Max.tensile load(KN) | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | |

Max.Working Torque(N.m) | 20 x 103 | 18 x 103 | 15 x 103 | 15 x 103 | 15 x 103 | 13 x 103 | |

Weight(KG) | Up | 1085 | 980 | 680 | 530 | 480 | 330 |

Down | 1027 | 920 | 645 | 520 | 457 | 310 | |

5.Lubricate with thread grease , connect jar with drill string according to specified

torque, and remove mandrel collar clamp by lifting of drill string.

Testing for releasing force of jar

6.2.1 Up jar 6.2.1.1 Adjust flow rate of pump on working table of jar tester to ensure speed of piston bar up to 450~650 mm/min, try to pull , and rating release force for up jar shall keep with data in table2. The max. release force for down jar shall meet with data in table

9. How to order

Specify: Name of spare steel parts ,

jar type If it is rubber part ,

specify rubber part name and jar type.

Special requirement if order jar in special specification and series.

.jpg)