|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

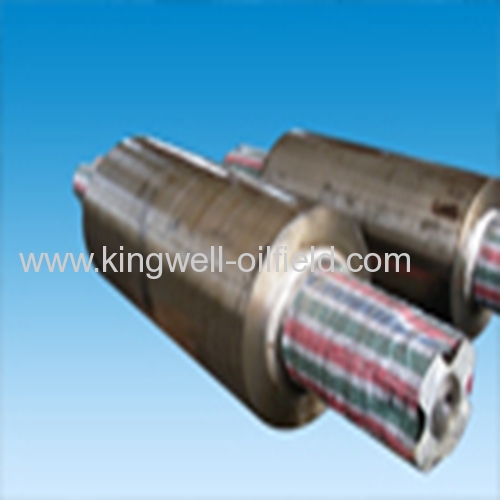

KINGWELL Rolling Mill Roll for the front 3 and 4 finishing racks of continuous strip mill and the post rack rough mill

| Price: | 1000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Rolling mill roll is an important part of the rolling machine,signed by both parties and other requirements.

Rolling Mill Roll

KW-FRG-05

KINGWELL Rolling Mill Roll Features & Benefits:

Rolling mill roll is an important part of the rolling machine. Under standard (GB / T) or technical agreement signed by both parties and other requirements. We are able to provide complete machining services such as boring, milling, turning, grinding, welding and fabrication. Usually we make it according to your drawing or requirements

KINGWELL Rolling Mill Roll Technical Data:

Name | Specification | Material |

Work Roll | Dia. 60~ Dia. 1000mm | 9Cr2Mo, 86CrMoV7,MC3,MC5,etc. |

Back Up Roll | Dia. 240~ Dia. 1000mm | 9Cr2Mo, MC3,MC5,etc. |

Intermediate Roll | ≤Dia. 1000mm | 9Cr2Mo, 86CrMoV7,MC3, etc. |

Leveling Roll | Dia. 60~ Dia.1000mm | 60CrMoV, H13, 80CrMoV, etc |

Table Roll | Dia. 100~ Dia. 1000mm | 1035, 1045, C35E, C40E, C45E, etc |

Pinch Roll | Dia. 80~ Dia. 1000mm | 1035, 1045, C35E, C40E, C45E, etc |

Driving Roll | Dia. 80~ Dia. 1000mm | 1035, 1045, C35E, C40E, C45E, etc |

Cradle Roll | Dia. 80~ Dia. 1000mm | 1035, 1045, C35E, C40E, C45E, etc |

Guide Roll | Dia. 80~ Dia. 1000mm | 1035, 1045, 4150, 4340, 4140, etc |

Piercing Roll | Dia. 80~ Dia. 1000mm | 1035, 1045, 4150, 4340, 4140, etc |

Straightening Roll | Dia. 80~Dia. 900mm | H13,4140,4340,EN9,EN19,EN24,EN31,51200,etc |

PROPERTIES

Thanks to its high content of M7C3, type carbide in range of 20-30% and discontinuous network distribution of carbide, the roll offers a high wear resistance performance. The matrix is finely-disseminated secondary carbides (M7C3,M23C5 and M3C types), increasing therefore the wear resistance of roll, The Cr2O3 enriched oxide film on the roll surfaces is highly resistant to oxidization and plastic strain, making the roll extremely suitable for steel hot milling process. | ||||||||||||

| ||||||||||||

APPLICATION | ||||||||||||

Mainly used for the front 3 and 4 finishing racks of continuous strip mill and the post rack rough mill. | ||||||||||||

Related products:

Alloy Cast Steel Roll

Alloy cast steel roll is made of top-grade molten steel by arc furnace and advanced casting and technology of heating processing with high intensity, excellent thermal cracking resistance, toughness and abrasive resistance, applicable to rough and medium roll of profile steel, rough mill of hot rolled strip steel and supporting roll of hot rolled strip steel. Metallographic structure of roll is made of pearlite or tempered sorbite system.

Chemical Composition

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adamite Rolls

Adamite roll is one kind of rolling materials whose performance is between steel roll and iron roll. It contains Ni, Cr and Mo elements, its matrix contains certain quantity of carbide which is processed with special thermal treatment technique with high abrasive resistance, strong toughness and good thermal resistance, its special characteristics is that there no hardness difference in working layer, applicable to rough milling and initial section of finishing mill for Tandem mill with steel; rough and medium milling of rod and wire milling machine, pre-finishing rack, universal mill, roll collar and roll jacket of cantilever mill. Chemical Composition

Performance and Application

| |||||||||||||||||||||||||||||||||||||||||||||||||

Graphitic Steel Roll

Performance of graphitic steel roll is similar to ferrosteel roll, its special characteristic is that there are a little of fine graphite in its structure, it is able to improve the thermal cracking resistance and adherence performance of antioxidant iron, mainly applicable to rough milling or blooming milled rack. Chemical Composition

Performance and Application

| |||||||||||||||||||||||||||||||||||||

High-speed Steel Roll

High-speed steel roll has high hardness and abrasive resistance under high

temperature. It is made by centrifuge method; the core part is made of nodular cast iron. Through component and heat treatment technique, the hardness in working layer is able to reach 80-85HSC; matrix in martensite contains V, W, Mo

compound carbide so as to assure the even hardness and aperture abrasion in working layer. This kind of roller is applicable to finishing rack to expand working period and improve surface quality of rolling materials.

Chemical Composition

Location | C | Si | Mn | W | V | Nb | Cr | Ni | Mo | Mg |

Working layer | 1.6-2.0 | 0.2-1.0 | 0.3-1.1 | 1.5-2.5 | 4.0-6.0 | 0.5-1.5 | 4.0-8.0 | 0.5-1.5 | 4.0-6.0 | |

Core part | 3.2-3.6 | 1.9-2.3 | 0.3-0.7 | ≤0.20 | 0.3-0.7 | 0.2-0.5 | ≥0.05 |

Performance and Application

Location | Hardness(HS) | Tensile strength(Mpa) | Elastic modulus(×103Mpa) | Purpose |

Working Layer | 80-85 | 700-900 | 210-240 | Working roll for hot rolled strip, finishing rack for altitude pre-finishing and tandem rolled rod |

GNV Roll

Roll for rough milling rack needs to be combined with certain characteristics, among of which, some characteristics will be cancelled out by the opposite side, including abrasive resistance, thermal cracking resistance, shock resistance, thermal hardness, thermal strength, etc. Excessive net carbide is able to improve the abrasive resistance, shock resistance which then lower the fracture toughness which then will result in production of thermal cracking under rough milling situations. Therefore, in order to reduce the influence of excessive carbide but also maintain the abrasive resistance, Ni and Mo must be added to let the matrix under bainite/ martensite (acicular) which is more wearable then ordinary matrix in pearlite. The Mo element is also good to improve harness of roll under high temperature.

GNV Roll is made of high alloy materials through special heat treatment, the

content of carbide in the matrix is lower than 5% so as to meet requirement from rough rolling rack.

Chemical Composition

Mark | C | Si | Mn | Cr | Ni | Mo | V |

GNV-A | 3.00-3.40 | 2.00-2.50 | 0.80-1.00 | ≥0.15 | 2.50-4.00 | 0.70-1.00 | 0.15-0.35 |

GNV-B | 3.00-3.40 | 1.50-2.00 | 0.80-1.00 | ≥0.15 | 2.50-4.50 | 0.70-1.00 | 0.15-0.35 |

Performance and Application

Mark | Hardness(HS) | Tensile strength(Mpa) | Bending strength(Mpa) | Purpose |

GNV-A | 40-50 | ≥510 | 900-1360 | Rough rolling rack for rod and wire materials |

.jpg)