|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

API Standard LPR-N Tester Valve

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Type: LPR-N Valve

Materiall:Alloy

Service:H2S, CO2

Standard:NACE MR0175

Operate:Full-opening, annulus press

DST Tools LPR-N Valve

General

The Pressure Operated tester valve (LPR-N Valve) is a full- opening, annulus pressure-operated valve. It measures multiple closed-in pressures in cased holes where pipe manipulation is restricted and a full-opening string is required. The nitrogen chamber is charged at the surface to a selected pressure determined by surface temperature, bottomhole temperature, and bottomhole pressure. If the intended test requires a permanent packer that uses a stinger mandrel or seal nipple, a variety of ENOC bypass tools are available, depending on field application, to help ensure that the formations and downhole equipment are protected from excessive pressure buildup.

Features and Benefits

• The ball valve operates independently of internal pressure changes, such as with acidizing or fracturing operations.

• Advanced materials and processes provide a unique metal-to-metal seat for exceptional gas-holding capabilities.

• The Pressure Poerated tester valve has been through an extensive five-day qualification testing at 400°F and15,000 psi burst and collapse pressures.

• An open-in feature allows the operator to run the Pressure Poerated tester in the hole with the ball valve opened or closed.

• Fluids can be spotted or circulated through the PRESSURE POERATED tester with the packer unseated.

A double nitrogen chamber can be added to the Pressure Poerated tester for use in deep, hot, high-pressure wells to reduce the operating pressure.

Operation

The Pressure Poerated tester valve is composed of a ball valve section, a power section, and a metering section.

The ball valve section provides multiple downhole closures. It is turned by operating arms. The power section has a floating piston that is exposed to the hydrostatic pressure on one side and pressurized nitrogen on the other side. With the packer set, pump pressure applied to the annulus moves the piston downward, activates the operating arms, and opens the ball valve. When the annulus pressure is released, pressurized nitrogen returns the piston upward, closing the ball.

After the surface equipment is properly installed, the packer is set, and the rams are closed, pressure is applied to the annulus, using rig pumps to operate the Pressure Poerated tester.

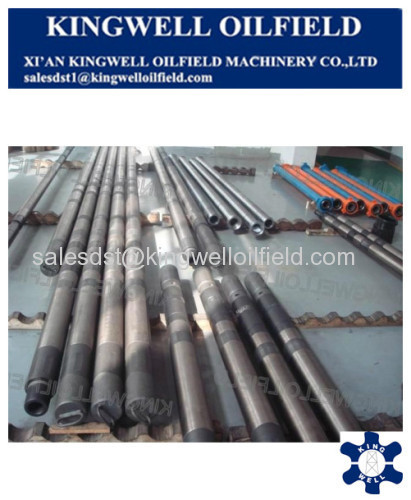

Pictures

Company Introduction

Xi'an Kingwell Oilfield Machinery Co.,Ltdis an established, financially stable manufacturing company and manufactured products are technically qualified which match the highest quality & reliability standards. We fulfill all the requirements to become a reliable supplier of any National and International majors in this field.

Here we got some prise as follows.

Certifications

Kingwell is a CNPC & SINOPEC & BV certified company, having all the Quality Systems in place for design, planning, manufacturing and quality monitoring & traceability to ensure our products match the highest quality standards.

We test our products strictly according to the NACE MR 0175-2002 Standard and our quality assurance period is 12 months.

Certificates endorsed by DNV/BV/ABS and Documents we can supply with the shipments:

1. Pressure Test Certificate with Graph and time recorded.

2. Function Test

3. Rubber Products NACE Compliance

4. Material Mill Certificate and treatment characteristics

5. H2S Compliance

6. Service Manual

7. Parts Manual

8. Testing Procedures.

9. Open up type tool drawing for dressing purpose– if any.

Design & Development

Kingwell has an ongoing relationship with Xi'an Petroleum University and built up long term cooperation with China Aerospace Group for more than 10 years. Design Department is familiar with CAD and Pro-E facilities and has on rolls qualified & experienced engineers. Now, they are engaged in development of new products as required in the market place. Kingwell' products are validated in-house in a Test Well, a Sub-surface Type Test Facility with simulated well conditions up to 15000 psi Differential pressure , 400°F and Max 450°F.

Manufacturing Facility

Equipped with latest machining facilities like CNC 3-axis Turning centers, CNC 4-axis milling centre, high temperature heat treatment furnaces, Centre lathe machines, Deep Hole Drilling, Boring & Honing machines, our company could meet long term production target and be governed efficiently by well-qualified and experienced Board of Directors and Engineers.

The following is the manufacturing workshop.

Training and Field Supports

We have a team of well qualified and experienced field support personnel for Training. According to customer's requirements, we provide operation training service for our customers who purchase our products.

Generally speaking, our customer training mainly includes followings:

1) To know the basic knowledge of the products, such as the usage, the working environments, the working principles, the structure, ect.

2) To learn the operation and use of products.

3) To master the basic requirement of designs of tool strings and of testing operation.

Product delivery

Payment:TT/LC:30% advance payment.70%before shipment

Warranty: Warranty period is 1 year after installation.

Origin: China

Minimum order: 1 set

Packaging: wood case or steel carton

Delivery Date: within 1-2 month(s) after receiving prepayment

Logo: KW, we can produce according to customer requirements.

Technical Documents: We can provide technical documents according to your requirements.

Additional service: Customers are served to test our products in our factory upon request.

Service

We believe in Customer delight, achieved by the supply of Quality Products & Services and Continual Improvement in our Manufacturing Processes for timely delivery at competitive prices. We work in a professional, competitive, and cost-effective manner consistent with the Customer requirement