|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

5" Round Mandrel SlipJoint Drill Stem Testing

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Type:Round Mandrel Slip Joint

Working condition:High pressure high temperature(HPHT)

Application:Drill stem testing

Service:H2S, CO2

Condition:New

KINGWELL Slip Joint Features & Benefits:

The slip joint is an expansion and contraction compensating tool, It accommodates any changes in string length

caused by temperature and pressure during a downhole test.

The slip joint has two distinct parts: an outer housing and a moving inner mandrel.

A slip joint operates by balancing its volume. As the slip joint stretches and increases its internal volume, a

differential piston within the slip joint allows the same volume of fluid into the pipe. The net result is no change

in internal volume.

Briefly Introduce

The round mandrel slip joint, like other slip joints, accepts the movement associated with ocean heave or

temperature change without allowing the movement to disturb the placement of downhole tools.

The round mandrel slip joint has the

following characteristics:

• Top of the mandrel slip joint has 4 3/4-in. (120.65-mm) drill collar profile for easy handling with the rig elevators and slips

• Maintains its full tensile rating when collapsed and locked

• Can be locked in the closed position for handling, reducing the risk of damage to the lifting/sealing mandrel

• Internally pressure and volume balanced

• String can be picked up with the slip joint locked; the slip joint can then be unlocked before it is run into the hole

• Provides free travel in the string to reciprocate tools without unseating the packer

A slip joint operates by balancing its volume. As the slip joint stretches and increases its internal volume, a differential piston within the slip joint allows the same volume of fluid into the pipe. The net result is no change in

internal volume.

Each slip joint has 5 ft (1.52 m) of travel but can be combined with other slip joints to provide additional travel.

When multiple slip joints are run, they are normally connected to one another rather than located throughout the pipe string. The number of slip joints required depends on ocean heave and the amount of expected contraction

and expansion.

Features and Benefits

• Provides a variable-length joint to allow the pipe to expand and contract during testing or stimulation

• Keeps vertical movement of the drilling vessel from disturbing tool placement

• Helps space out the testing string when the subsea tree is landed

• Provides a constant weight on the packer during testing or stimulation

Operation

The weight of the toolstring (excluding tools, anchor, and traveling blocks) is used to determine the location of the slip joint. Once the necessary packer-setting weight is shown on the weight indicator, the slip joint is placed into the string.

When multiple slip joints are used, the top joint makes its complete travel, then the next joint down makes its travel, and so on. The weight indicator may show a slight bump as each slip joint reaches the end of its travel.

A pressure test can be performed on the entire 5-ft (1.52-m) length of the sealing mandrel OD.

Specifications:

1. Halliburton type, all could change with Halliburton parts.

2. All equipments are produced according to API standard NACE MRO175-2002

Below are spec for you reference:

Nominal Tool Size in. | OD in. (cm) | ID in. (cm) | Thread Connections | Tempera tire' *F (*C) | Length in. (cm) | Stroke Length1 in.(cm) | Tensile Rating** lb (Kg) | Working Pressure** psi (bar) |

37/8 | 3.90 (9.91) | 1.80 (4.57) | 2 7/8 CAS | 450 (232) | 76.25 (193.68) | 60.00 (152.4) | 416,000 (188 689) | 15,000 (1034) |

5.00 | 5.03 (12.78) | 2.28 (5.79) | 3 7/8 CAS | 450 (232) | 76.25 (193.68) | 60.00 (152.4) | 416,000 (188 689) | 15,000 (1034) |

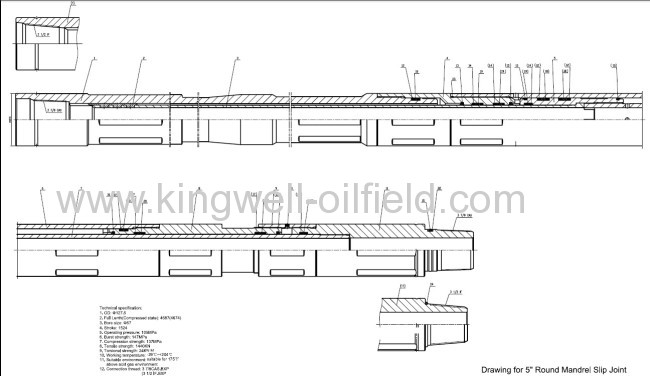

Drawing

Picture

Company Introduction

Xi'an Kingwell Oilfield Machinery Co.,Ltdis an established, financially stable manufacturing company and manufactured products are technically qualified which match the highest quality & reliability standards. We fulfill all the requirements to become a reliable supplier of any National and International majors in this field.

Here we got some prise as follows.

Design & Development

Kingwell has an ongoing relationship with Xi'an Petroleum University and built up long term cooperation with China Aerospace Group for more than 10 years. Design Department is familiar with CAD and Pro-E facilities and has on rolls qualified & experienced engineers. Now, they are engaged in development of new products as required in the market place. Kingwell' products are validated in-house in a Test Well, a Sub-surface Type Test Facility with simulated well conditions up to 15000 psi Differential pressure , 400°F and Max 450°F.

Manufacturing Facility

Equipped with latest machining facilities like CNC 3-axis Turning centers, CNC 4-axis milling centre, high temperature heat treatment furnaces, Centre lathe machines, Deep Hole Drilling, Boring & Honing machines, our company could meet long term production target and be governed efficiently by well-qualified and experienced Board of Directors and Engineers.

Inspection and Test Facilities

We own the world-class facilities with professional laboratory technicians. The main facilities are Surface Testing (Hydraulic Testing Unit), high temperature heat treatment furnaces, API Gages (Master & Working), Profile Projector, tensile testing machine, pressure sensor and data acquisition system, Universal Testing Machine, Hardness Tester, Nitrogen Pump, Function Test Pump, Ultrasonic Thickness Tester etc. All the goods must be tested by several processes and must be qualified when packed.

The followings are some pictures of Test Facility

We believe in Customer delight, achieved by the supply of Quality Products & Services and Continual Improvement in our Manufacturing Processes for timely delivery at competitive prices. We work in a professional, competitive, and cost-effective manner consistent with the Customer requirement

We are looking forward towards a long lasting association with your esteemed organization for our mutual benefit. Any reasonable documents with the shipments depend on your requirements. Please contact us for any enquiry within our manufacturing scope and we will be happy to serve you by supplying quality products.