|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

Drill Stem Testing Tools Hdraulic Jar from Kingwell Oilfield

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

product model:Hydraulic Jar

Type:Halliburton

size:3 7/8"

Application:Drill stem testing

Working pressure:10000psi ~ 15000psi

Service:H2S, CO2

DST tools 3 7/8" Hydraulic Jar

Type:Halliburton

Size:3 7/8"

Application:Drill stem testing

Working pressure:10000psi ~ 15000psi

Working condition:High pressure high temperature(HPHT)

Standard: API(American Petroleum Institute);

Service:H2S, CO2

Condition: New

Briefly Introduce

The hydraulic jar is included as part of a toolstring to help remove stuck tools. The jar helps free a

stuck tool or toolstring by resisting a pull on the workstring. When the workstring is stretched by

the pull, tension in the jar is released and an upward impact is delivered to the stuck tool.

Features and Benefits

• Design of the hydraulic system ensures long life with little maintenance.

• Rig time is reduced.

• Jar can be recocked rapidly.

• Jar time delay is adjustable.

• Amount of pull to trip the jar can be varied within the limits of the time-delay system.

Operation

The temporary resistance that powers the jar is provided by a hydraulic time-delay system.Resistance is released when the metering sleeve inside the jar moves into a bypass section of the outer case. This action allows the special hydraulic oil to bypass rapidly.

The time delay required to release the temporary resistance varies in relation to the weight of the pull. For example, a light pull requires more time for release than a hard pull. When tools below the jar are stuck, a steady pull applied to the jar creates an upward impact blow to the string. The jar can be recocked when

the string is set down.

Specifications:

1. Halliburton type, all could change with Halliburton parts.

2. All equipments are produced according to API standard NACE MRO175-2002

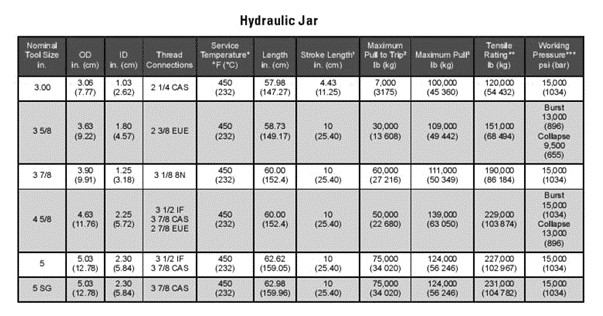

Below are specfor you reference:

Company Introduction

Xi'an Kingwell Oilfield Machinery Co.,Ltd is an established, financially stable manufacturing company and manufactured products are technically qualified which match the highest quality & reliability standards. We fulfill all the requirements to become a reliable supplier of any National and International majors in this field.

Manufacturing Facility

Equipped with latest machining facilities like CNC 3-axis Turning centers, CNC 4-axis milling centre, high temperature heat treatment furnaces, Centre lathe machines, Deep Hole Drilling, Boring & Honing machines, our company could meet long term production target and be governed efficiently by well-qualified and experienced Board of Directors and Engineers.

The following is the manufacturing workshop.

Training and Field Supports

We have a team of well qualified and experienced field support personnel for Training. According to customer's requirements, we provide operation training service for our customers who purchase our products.

Generally speaking, our customer training mainly includes followings:

1) To know the basic knowledge of the products, such as the usage, the working environments, the working principles, the structure, ect.

2) To learn the operation and use of products.

3) To master the basic requirement of designs of tool strings and of testing operation.

Related products

We also provide accessories and other related products, which you can find in this website.

The following is the pictures about products accessories and some other related products

Product delivery

Payment:TT/LC:30% advance payment.70%before shipment

Warranty: Warranty period is 1 year after installation.

Origin: China

Minimum order: 1 set

Packaging: wood case or steel carton

Delivery Date: within 1-2 month(s) after receiving prepayment

Logo: KW, we can produce according to customer requirements.

Technical Documents: We can provide technical documents according to your requirements.

Additional service: Customers are served to test our products in our factory upon request.

The followings are some pictures about product packaging

If any needs, pls contact salesdst@kingwelloilfield.com

.jpg)