|

XI'AN KINGWELL OILFIELD MACHINERY CO.,LTD

|

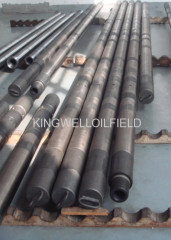

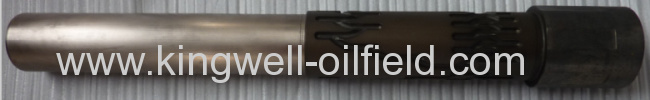

Cased Hole Drill Stem Testing Tools(DST) safety joint parts

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Working condition:High pressure high temperature(HPHT)

Size: 4 1/2"

service:H2S, CO2

Working pressure:10000psi ~ 15000psi

Condition: New

Working condition:High pressure high temperature(HPHT)

Size: 4 1/2"

service:H2S, CO2

Working pressure:10000psi ~ 15000psi

Condition: New

Cased Hole Drill Stem Testing Tools(DST) safety joint parts

Quality Systems

A well-established Quality System from Materials receipt to Products delivery ensures consistent quality at all levels of the activity. QMS Procedures & Measurements are tailored to establish high standards of Quality Assurance in the Operations. The Company maintains the 100% Traceability records as per API requirements &NACE MR 0175-2002 Standards and complies with all the legal, statutory and regulatory requirements.

1. Quality control of the spring: Apart from the conventional test of the raw material and size of the different springs that used in the tools, we specially designed a test device that equipped with heating preservation equipment to stimulate the down hole temperature and condition to test the spring performance.

4. Quality control of the spare parts processing:

1) Spare parts processing control:In strict accordance with the process and traceability requirements, a test, mark and record of dimension, geometric tolerance and for every piece and every procedure will be conduct.

2) Heat treatment quality control: We have two high temperature heat treatment furnaces that are mainly used for stainless steel and other special material heat treatment. For other materials, we entrust Baoji Petroleum Machinery Company Heat Treatment Plant to do the heat treatment. For the inspection of the heat treatment, we are equipped with the special inspection machine such as gantry hardness tester, digital universal tensile tester etc.

2. Quality control of the tool assembly and testing process

1) Test equipment: in addition to the conventional hydraulic test pump, tensile testing machine, we also have a pressure sensor and data acquisition system which can accurate and clear record each step of the test.

2) Technical documents: We have a test acceptance list for every tool test that clearly guides the each step of the test.

3) Assembly test: A special inspector will supervise the whole assembly process.

| Item | Part No. | Production name | Unit | Qty of each set | 10 Run Spare parts |

| 10 Run spare parts FOR 7"RTTS Packer | |||||

| 1 | KW552103-02.00 | Hydraulic slip | pcs | 6 | 30 |

| 2 | KW552103-03 | Spring | pcs | 12 | 20 |

| 3 | KW552103-06a | Top shoe 3238Lb/ft(143.51) | pcs | 1 | 2 |

| 4 | KW552103-06b | Top shoe 2329Lb/ft(146.05) | pcs | ||

| 5 | KW552103-06c | Top shoe 1726Lb/ft(152.40) | pcs | ||

| 6 | KW552103-07a.01d07a.04d | Packer Rubber142.7(3238Lb/ft) nitrile rubber | pcs | 2 | 20 |

| 7 | KW552103-07b.01d07b.04d | Packer Rubber144.8(2329Lb/ft) nitrile rubber | pcs | ||

| 8 | KW552103-07c.01d07c.04d | Packer Rubber151.1(1726Lb/ft) nitrile rubber | pcs | ||

| 9 | KW552103-08 | Retainer | pcs | 1 | 2 |

| 10 | KW552103-09a | Bottom shoe 3238Lb/ft(143.51) | pcs | 1 | 2 |

| 11 | KW552103-09b | Bottom shoe 2329Lb/ft(146.05) | pcs | ||

| 12 | KW552103-09c | Bottom shoe 1726Lb/ft(152.40) | pcs | ||

| 13 | KW552103-12.00 | Slip | pcs | 6 | 30 |

| 14 | KW552103-13 | Bolt | pcs | 3 | 8 |

| 15 | KW552103-15.00 | Drag Block | pcs | 4 | 10 |

| 16 | 2-334 | O-Ring | pcs | 1 | 10 |

| 17 | KW552103-16 | Slip Bolt | pcs | 13 | 20 |

| 18 | 2-330 | O-Ring | pcs | 6 | 60 |

| 19 | 2-339 | O-Ring | pcs | 2 | 20 |

| 20 | KW652203-12 | Slip shotpin | pcs | 6 | 10 |

| 21 | 2-231 | O-Ring | pcs | 1 | 10 |

| 22 | 2-233 | O-Ring | pcs | 1 | 10 |

| 23 | KW652203-19 | Drag Block Spring | pcs | 16 | 20 |

| 24 | KW652203-20 | Lock block | pcs | 4 | 10 |

| 25 | 2-240 | O-Ring | pcs | 1 | 10 |

| 26 | 2-342 | O-Ring | pcs | 1 | 10 |

| 27 | KW003-19 | support surface sealing | pcs | 2 | 10 |

| 10 Run spare parts FOR 7"RTTS Safety Joint | |||||

| 1 | KW552304-06 | sleeve | pcs | 1 | 10 |

| 2 | 2-344 | O-Ring | pcs | 1 | 10 |

| 3 | 2-336 | O-Ring | pcs | 1 | 10 |

| 4 | 2-241 | O-Ring | pcs | 1 | 10 |

| 5 | 2-337 | O-Ring | pcs | 1 | 20 |

| 6 | 2-343 | O-Ring | pcs | 1 | 10 |

| 7 | 2-342 | O-Ring | pcs | 1 | 10 |

| 10 Run spare parts FOR 7" RTTS circulating valve | |||||

| 1 | 2-232 | O-Ring | pcs | 1 | 10 |

| 2 | 2-337 | O-Ring | pcs | 2 | 20 |

| 3 | 2-144 | O-Ring | pcs | 2 | 20 |

| 4 | KW552302-07 | O-Ring | pcs | 3 | 10 |

| 5 | 2-344 | O-Ring | pcs | 2 | 30 |

| 6 | 2-240 | O-Ring | pcs | 1 | 10 |

| 10 Run spare parts FOR 9 5/8″RTTS Packer (29.3-43.5#) | |||||

| 1 | KW652310A-02.00 | Hydraulic slip | pcs | 12 | 24 |

| 2 | KW652310A-04 | Spring | pcs | 24 | 48 |

| 3 | KW652310A-13.00 | Slip | pcs | 8 | 16 |

| 4 | KW652310A-18.00 | Drag Block | pcs | 8 | 16 |

| 5 | KW652310A-19 | Drag Block Spring | pcs | 32 | 64 |

| 6 | KW652310A-06.01 | Packer Rubber(29.3#43.5#) Fluoro Rubber | pcs | 2 | 20 |

| 7 | 2-349 | O-Ring (Fluoro Rubber ) | pcs | 2 | 20 |

| 8 | 2-432 | O-Ring (Fluoro Rubber ) | pcs | 2 | 20 |

| 9 | 2-426 | O-Ring (Fluoro Rubber ) | pcs | 1 | 10 |

| 10 | 2-247 | O-Ring (Fluoro Rubber ) | pcs | 1 | 10 |

| 11 | 2-250 | O-Ring (Fluoro Rubber ) | pcs | 1 | 10 |

| 12 | 2-332 | O-Ring (Fluoro Rubber ) | pcs | 12 | 120 |

| 10 Run spare parts FOR 9 5/8″RTTS Safety Joint | |||||

| 1 | KW352101-06 | Sleeve | pcs | 1 | 10 |

| 2 | 2-249 | O-Ring | pcs | 1 | 10 |

| 3 | 2-248 | O-Ring | pcs | 1 | 10 |

| 4 | 2-342 | O-Ring | pcs | 1 | 10 |

| 5 | 2-344 | O-Ring | pcs | 2 | 20 |

| 6 | 2-250 | O-Ring | pcs | 1 | 10 |

| 10 Run spare parts FOR 9 5/8″RTTS Circulating Valve | |||||

| 1 | 2-341 | O-Ring (Fluoro Rubber ) | pcs | 1 | 10 |

| 2 | 2-344 | O-Ring (Fluoro Rubber ) | pcs | 2 | 20 |

| 3 | KW652302-06 | O-Ring (Fluoro Rubber ) | pcs | 3 | 30 |

| 4 | 2-236 | O-Ring (Fluoro Rubber ) | pcs | 1 | 10 |

| 5 | 2-425 | O-Ring (Fluoro Rubber ) | pcs | 1 | 10 |

| 6 | 2-250 | O-Ring (Fluoro Rubber ) | pcs | 1 | 10 |

The following is the pictures about products accessories and some other related products

transposltlon mandrel

ball valve assembly

measuring set

Training and Field Supports

We have a team of well qualified and experienced field support personnel for Training. According to customer's requirements, we provide operation training service for our customers who purchase our products.

Generally speaking, our customer training mainly includes followings:

To master the basic requirement of designs of tool strings and of testing operation.

Product delivery

Payment:TT/LC:30% advance payment.70%before shipment

Warranty: Warranty period is 1 year after installation.

Origin: China- Minimum

Order: 1 set

Packaging: wood case or steel carton

Delivery Date: within 1-2 month(s) after receiving prepayment

Logo: KW, we can produce according to customer requirements.

Technical Documents: We can provide technical documents according to your requirements.

Service

We believe in Customer delight, achieved by the supply of Quality Products & Services and Continual Improvement in our Manufacturing Processes for timely delivery at competitive prices. We work in a professional, competitive, and cost-effective manner consistent with the Customer requirement.

Kindly let me know if you have any interest or enquiry about our products. You are also always welcomed to come to our factory for a visit at your convenient time.We will offer you a good price and show you our best service

.jpg)